Clearer Grasp of a Slippery Material

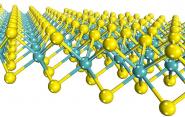

Molybdenum disulfide is slippery stuff.

In addition to its common use as a lubricant—it keeps critical machine parts, like airplane engines, slickly moving even during total oil loss—experiments have shown that single-layer forms of the compound could be a promising material for constructing next-generation electronics.

The key is greater electron mobility, an essential quality for the compound to be useful in thin film transistors, image sensors, and solar cells, for example. Now, researchers have shown that molybdenum disulfide has far greater potential to travel than believed.

“Initially, we found a very low mobility. But after careful analysis, we noticed there are in fact two types of charge carriers,” says Fengnian Xia, an assistant professor in Yale’s electrical engineering department and an author of a paper published online in Nature Communications Jan. 17. “Some carriers are trapped within the band gap, so these carriers are not really mobile. But the other carriers are in the band, where they exhibit much higher mobility.”

Previous experiments reported conflicting accounts of the compound’s electron mobility—a parameter that indicates how fast a given compound’s electrons can move under an applied electric field—and recent ones found it to be unusably low.

Xia and his collaborators determined that the contradictory results in previous experiments likely stem from variations in the source of material, the processing steps, and the local environment of the devices.

Moreover, early experiments in the field used the “scotch tape technique,” where a piece of tape is used to repeatedly peel flakes off a lump of molybdenum disulfide until a tiny, single-layer area is produced. The resulting micrometer-sized fragments are placed between electrodes to make a transistor.

“But that is not viable for large-scale production, for obvious reasons,” Xia says.

Xia’s team instead created large single-layer sheets of molybdenum disulfide for their experiment using a recently developed mass-production technique known as chemical vapor deposition. It was with this technique that the researchers discovered the trapped carriers and identified the cause of the lowered mobility.

“We know these trapped carriers are not intrinsic to the material,” says Xia. “With future improvements in the material quality, we will move all the carriers to the band, increasing mobility significantly.”

Xia worked with Wenjuan Zhu, Tony Low, Han Wang, Damon Farmer, Phaedon Avouris at IBM, Jing Kong at MIT, and Yi-Hsien Lee at Taiwan’s National Tsing Hua University.