MENG 472/474 Projects - Spring 2019

In MENG 472/474, students work on independent projects that cover a wide range of topics, from traditional mechanical engineering topics (e.g., mechanical device design, fluid flow, and materials analysis) to interdisciplinary topics at the interface between mechanical engineering and other branches of engineering such as biomedical, chemical, electrical, or environmental engineering. Under the supervision of faculty advisers, students investigate physical phenomena through experimental measurement and/or numerical simulation, and they design and construct functioning prototypes to solve engineering problems. The majority of the faculty advisers come from within the mechanical engineering department, with the remaining advisers distributed across the University (and occasionally outside the University). Funding for projects is generously provided by the Yale SEAS Dean's Office and, in some cases, through the faculty advisers. The students were asked to write the following short summaries two-thirds of the way through the semester, when they still had a few weeks to go on their projects. All projects are represented here, except for those that cannot be publicized due to information of a proprietary nature.

Polymeric Micro Pillars for Low-Impact Dust Particle Cleaning

M. Anwar Akkari

Adviser: Dr. Hadi Izadi

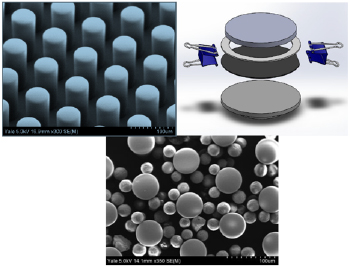

Removal of dust particles from solid surfaces has been the subject of extensive research over the years as scientists seek to develop increasingly efficient and cost effective techniques to address this challenge. Developing such techniques would be useful in various domains such as art conservation and microelectronics. While the elimination of large (>10 μm) particles is simple, existing techniques for removing sub-micrometer particles (particularly < 0.3 μm) are relatively expensive, time-consuming, and more importantly, destructive. Using polymeric pillars with specified geometric properties, an ongoing Yale research project has managed to effectively remove dust particles without damaging surfaces. My work within this project is to design, fabricate and test the setup required to adapt this cleaning technique to remove contamination from semiconductor surfaces. I used 3D rapid prototyping to execute the setup design required for the soft lithography approach that has been used for fabrication of μ-dusters. The setup was then manufactured and tested in terms of reliability and effectiveness. Now, our goal is to develop this prototype to produce a marketable and industrially feasible dust cleaning device that can be used within the semiconductor industry (Silicon and GaAs).

Removal of dust particles from solid surfaces has been the subject of extensive research over the years as scientists seek to develop increasingly efficient and cost effective techniques to address this challenge. Developing such techniques would be useful in various domains such as art conservation and microelectronics. While the elimination of large (>10 μm) particles is simple, existing techniques for removing sub-micrometer particles (particularly < 0.3 μm) are relatively expensive, time-consuming, and more importantly, destructive. Using polymeric pillars with specified geometric properties, an ongoing Yale research project has managed to effectively remove dust particles without damaging surfaces. My work within this project is to design, fabricate and test the setup required to adapt this cleaning technique to remove contamination from semiconductor surfaces. I used 3D rapid prototyping to execute the setup design required for the soft lithography approach that has been used for fabrication of μ-dusters. The setup was then manufactured and tested in terms of reliability and effectiveness. Now, our goal is to develop this prototype to produce a marketable and industrially feasible dust cleaning device that can be used within the semiconductor industry (Silicon and GaAs).

Geometric Cohesion of n-Mer Chains

Theo Evers

Adviser: Prof. Corey O'Hern, Mechanical Engineering & Materials Science

Our current research is to use discrete element simulations to model the mechanical response of piles of U-shaped particles to tensile forces. Specifically, we will measure the force required to pull one of the particles out of the stack. We will model U-shaped particles by a series of spheres linked together in the shape of a U. This semester I have been developing a computer simulation to generate mechanically stable packings of disks that are mechanically stable. (See Fig. 1 below.) This is a crucial first step in developing a simulation to study the response of U-shaped particles composed of spheres.

Our current research is to use discrete element simulations to model the mechanical response of piles of U-shaped particles to tensile forces. Specifically, we will measure the force required to pull one of the particles out of the stack. We will model U-shaped particles by a series of spheres linked together in the shape of a U. This semester I have been developing a computer simulation to generate mechanically stable packings of disks that are mechanically stable. (See Fig. 1 below.) This is a crucial first step in developing a simulation to study the response of U-shaped particles composed of spheres.