MENG 472/474 Projects - Spring 2016

In MENG 472b, students work on independent projects that cover a wide range of topics, from traditional mechanical engineering topics (e.g., mechanical device design, fluid flow, and materials analysis) to interdisciplinary topics at the interface between mechanical engineering and other branches of engineering such as biomedical, chemical, electrical, or environmental engineering. Under the supervision of faculty advisers, students investigate physical phenomena through experimental measurement and/or numerical simulation, and they design and construct functioning prototypes to solve engineering problems. The majority of the faculty advisers come from within the mechanical engineering department, with the remaining advisers distributed across the University (and occasionally outside the University). Funding for projects is generously provided by the Yale SEAS Dean's Office and, in some cases, through the faculty advisers. The students were asked to write the following short summaries two-thirds of the way through the semester, when they still had a few weeks to go on their projects.

Basic Research

Synthesis flexibility of copper oxide nanoparticles

Bolun Liu

Adviser: Professor Lisa Pfefferle, Chemical and Environmental Engineering

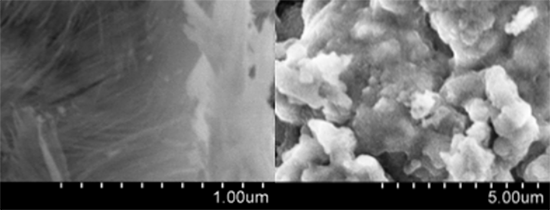

Our current research follows from work done at the Catalytic Combustion Lab, when a need for a broader understanding of synthesis techniques for copper oxide nanostructures arose. We are using a three-level fractional factorial design to explore the possible parameter space around one particular synthesis method that has been successful in the past. We have chosen to base our research on a wet synthesis technique involving copper nitrate and sodium hydroxide. Many of our synthesis procedures are promising. We produce nanosheets, nanowires, and nanoparticles, do not require lengthy low-temperature post-annealing to remove insolvable chemicals, and do not require as slow a filtering process. Our co-solvents, sodium chloride and ethanol, are low-cost, environmentally friendly, and have an impact on nanostructure, although the nature of the relationship is an ongoing investigation. We have also found that the bounds for the synthesis technique are between 0% and 20% by mass for ethanol, and between 0.5 and 0.005 molar for sodium hydroxide. Although this research is ongoing, we have successfully determined some of the bounds in which successful nanostructure synthesis lies, and proven that a variety of nanostructures can be produced, as shown in the image. Our current research follows from work done at the Catalytic Combustion Lab, when a need for a broader understanding of synthesis techniques for copper oxide nanostructures arose. We are using a three-level fractional factorial design to explore the possible parameter space around one particular synthesis method that has been successful in the past. We have chosen to base our research on a wet synthesis technique involving copper nitrate and sodium hydroxide. Many of our synthesis procedures are promising. We produce nanosheets, nanowires, and nanoparticles, do not require lengthy low-temperature post-annealing to remove insolvable chemicals, and do not require as slow a filtering process. Our co-solvents, sodium chloride and ethanol, are low-cost, environmentally friendly, and have an impact on nanostructure, although the nature of the relationship is an ongoing investigation. We have also found that the bounds for the synthesis technique are between 0% and 20% by mass for ethanol, and between 0.5 and 0.005 molar for sodium hydroxide. Although this research is ongoing, we have successfully determined some of the bounds in which successful nanostructure synthesis lies, and proven that a variety of nanostructures can be produced, as shown in the image. |

Combining the scanning tunneling microscope probe with the atomic force microscope tuning fork

Taha Ramazanoğlu

Adviser: Professor Udo Schwarz, Mechanical Engineering and Materials Science

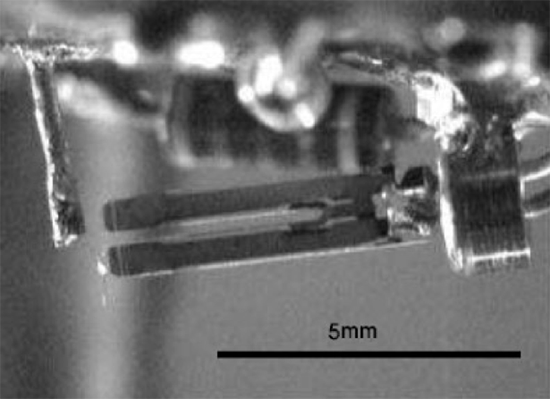

Getting a better understanding of the microstructure of materials that defines their characteristics requires the ability to observe the interactions at the atomic resolution. Combining the scanning tunneling microscope and the atomic force microscope enables us to merge their advantages into one solution. Modifying the atomic force microscope’s tuning fork that is used to detect the physical topology of materials by placing a voltage-carrying probe on it, we are able to implement the scanning tunneling microscope’s ability to detect the positions of individual atoms. The external wire solution to apply the bias voltage, as seen in the picture, is currently used in the lab but was not found satisfactory due to the damping effect of the wire on the tuning fork. We are now depositing a film of epoxy on the tuning fork to first insulate it, and then a layer of gold to carry the voltage to the probe. We are expecting the attenuation on the natural frequency of the tuning fork due to the additional mass to be much less compared to the external wire solution, and we have designed a vise mechanism that holds the tuning fork during the depositions to improve the quality and repeatability of the processes. Getting a better understanding of the microstructure of materials that defines their characteristics requires the ability to observe the interactions at the atomic resolution. Combining the scanning tunneling microscope and the atomic force microscope enables us to merge their advantages into one solution. Modifying the atomic force microscope’s tuning fork that is used to detect the physical topology of materials by placing a voltage-carrying probe on it, we are able to implement the scanning tunneling microscope’s ability to detect the positions of individual atoms. The external wire solution to apply the bias voltage, as seen in the picture, is currently used in the lab but was not found satisfactory due to the damping effect of the wire on the tuning fork. We are now depositing a film of epoxy on the tuning fork to first insulate it, and then a layer of gold to carry the voltage to the probe. We are expecting the attenuation on the natural frequency of the tuning fork due to the additional mass to be much less compared to the external wire solution, and we have designed a vise mechanism that holds the tuning fork during the depositions to improve the quality and repeatability of the processes. |

Biomechanics Research

Contribution of the transverse arch to foot stiffness

Lucia Korpas

Adviser: Professor Madhusudhan Venkadesan, Mechanical Engineering and Materials Science

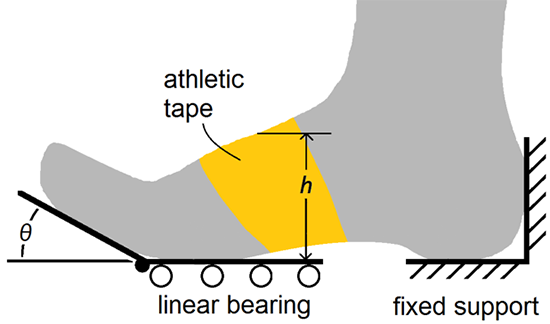

We are investigating how compression of the transverse arch, along the width of the foot, affects overall foot stiffness (i.e., resistance to deformation under load). The windlass mechanism, in which flexing the toes upward induces an increase in the arch height, is used to load the foot. We have designed and built a platform, as shown in the image, to raise the toes while reducing the effect of friction on the observed change in arch height. During data collection, we are tracking the movement of the top of the arch as the toes are raised for two conditions for each subject: the arch compressed by wrapping athletic tape around the midfoot, and the uncompressed arch. We have currently collected data from two subjects. Preliminary results indicate that an increase in the strain on the tape decreases the height to which the arch can rise for a given toe angle, which implies an increase of the stiffness of the foot. We will collect foot deformation data from several other subjects to confirm this result. Ultimately, we hope to compare our results against an existing theoretical model. We are investigating how compression of the transverse arch, along the width of the foot, affects overall foot stiffness (i.e., resistance to deformation under load). The windlass mechanism, in which flexing the toes upward induces an increase in the arch height, is used to load the foot. We have designed and built a platform, as shown in the image, to raise the toes while reducing the effect of friction on the observed change in arch height. During data collection, we are tracking the movement of the top of the arch as the toes are raised for two conditions for each subject: the arch compressed by wrapping athletic tape around the midfoot, and the uncompressed arch. We have currently collected data from two subjects. Preliminary results indicate that an increase in the strain on the tape decreases the height to which the arch can rise for a given toe angle, which implies an increase of the stiffness of the foot. We will collect foot deformation data from several other subjects to confirm this result. Ultimately, we hope to compare our results against an existing theoretical model. |

Body orientation stability during two-legged jumping

Alexander Lee

Adviser: Professor Madhusudhan Venkadesan, Mechanical Engineering and Materials Science

In two-legged jumping, a person’s body provides shear and moment forces to compensate for differences in vertical force provided by the legs. The purpose of this project was to determine the effects of shear and moment forces, applied at the feet, upon body orientation stability during two-legged jumping. We collected velocity data at 200 times a second at 16 points on a mechanical jumper using three Vicon T20-S motion-tracking cameras and analyzed this data in Matlab to calculate the angular and linear momentum as a function of applied force. We varied the force application to the jumper’s legs to find the relationship between force and momentum for our jumper. We anticipate finding that both types of forces contribute to body orientation stability but that shear forces contribute more heavily than moment forces. Our final results will be presented in the form of a figure that plots the angular momentum against the linear momentum for all four combinations of force: shear, moment, both, and none. Our results have the potential to impact the field of robotics and further collective understanding of biological two-legged jumping. Moving forward, we recommend further investigation of the effect of moment and shear forces upon biological subjects. In two-legged jumping, a person’s body provides shear and moment forces to compensate for differences in vertical force provided by the legs. The purpose of this project was to determine the effects of shear and moment forces, applied at the feet, upon body orientation stability during two-legged jumping. We collected velocity data at 200 times a second at 16 points on a mechanical jumper using three Vicon T20-S motion-tracking cameras and analyzed this data in Matlab to calculate the angular and linear momentum as a function of applied force. We varied the force application to the jumper’s legs to find the relationship between force and momentum for our jumper. We anticipate finding that both types of forces contribute to body orientation stability but that shear forces contribute more heavily than moment forces. Our final results will be presented in the form of a figure that plots the angular momentum against the linear momentum for all four combinations of force: shear, moment, both, and none. Our results have the potential to impact the field of robotics and further collective understanding of biological two-legged jumping. Moving forward, we recommend further investigation of the effect of moment and shear forces upon biological subjects. |

Estimation of bone surface curvatures

Xuan-Truc Nguyen

Adviser: Professor Madhusudhan Venkadesan, Mechanical Engineering and Materials Science

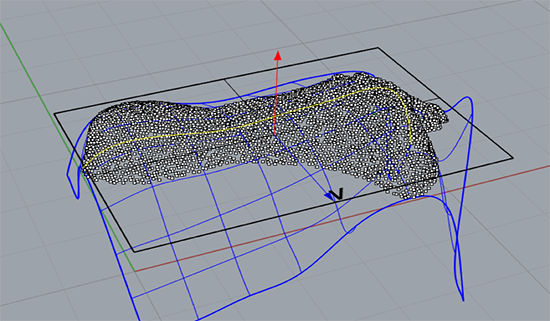

Paleontologists and anthropologists will often use the shape of bones to determine their function and how they interacted with neighboring bones. However, there is currently no mathematically rigorous method of analyzing bones. In order to quantitatively characterize bone shape, we are using non-uniform rational B-splines (NURBS) to fit the bone surfaces to functions. We used VGStudio MAX (a CT visualization and analysis software) to extract surface data in the form of point clouds from high-resolution CT scans of fossils. We are using MATLAB to generate the NURBS functions to smooth our data and to perform analysis on both generated test surfaces with known curvatures and arbitrary bone surfaces. We will use these functions to calculate surface curvatures of various bones, which will allow us to compare bones within and across species. We hope to achieve a new general method of quantitatively characterizing bone shapes, and particularly curvatures. Paleontologists and anthropologists will often use the shape of bones to determine their function and how they interacted with neighboring bones. However, there is currently no mathematically rigorous method of analyzing bones. In order to quantitatively characterize bone shape, we are using non-uniform rational B-splines (NURBS) to fit the bone surfaces to functions. We used VGStudio MAX (a CT visualization and analysis software) to extract surface data in the form of point clouds from high-resolution CT scans of fossils. We are using MATLAB to generate the NURBS functions to smooth our data and to perform analysis on both generated test surfaces with known curvatures and arbitrary bone surfaces. We will use these functions to calculate surface curvatures of various bones, which will allow us to compare bones within and across species. We hope to achieve a new general method of quantitatively characterizing bone shapes, and particularly curvatures. |

Unraveling the significance of the tenodesis effect for human throwing

Petter Wehlin

Adviser: Professor Madhusudhan Venkadesan, Mechanical Engineering and Materials Science

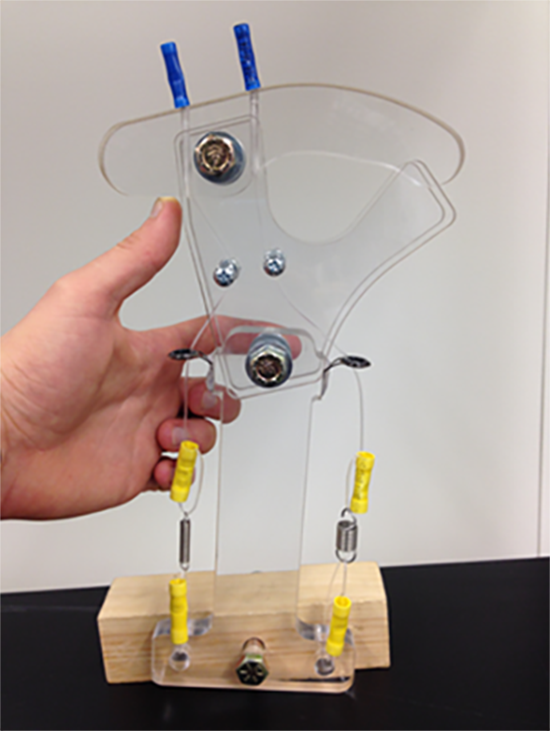

The biomechanics of human throwing are yet to be fully understood. However, in the Yale Biomechanics and Control Lab we have developed a hypothesis that might answer the question about what enables humans’ unique throwing abilities. The centerpiece of our hypothesis is the tenodesis effect, which is a mechanical coupling between the wrist angle and the opening angles of a person’s fingers. To test our proposition we have built a model of the human arm, which incorporates the tenodesis effect, and tested its throwing capabilities. We found that we faced three main obstacles that prevented us from measuring the arm’s full throwing potential. The obstacles were: deflection of our projectile caused by the shape of the finger, suboptimal opening angle of the finger caused by incorrect lengths and elastic moduli of the tendons, and excessive oscillations caused by an underdamped response. We are currently addressing these obstacles by redesigning the finger, and by using a mathematical model to optimize the static and dynamic characteristics of the throwing arm. We will then be able to measure the full throwing potential of our model and compare it to other throwing mechanisms, to ultimately prove or disprove our hypothesis about human throwing. The biomechanics of human throwing are yet to be fully understood. However, in the Yale Biomechanics and Control Lab we have developed a hypothesis that might answer the question about what enables humans’ unique throwing abilities. The centerpiece of our hypothesis is the tenodesis effect, which is a mechanical coupling between the wrist angle and the opening angles of a person’s fingers. To test our proposition we have built a model of the human arm, which incorporates the tenodesis effect, and tested its throwing capabilities. We found that we faced three main obstacles that prevented us from measuring the arm’s full throwing potential. The obstacles were: deflection of our projectile caused by the shape of the finger, suboptimal opening angle of the finger caused by incorrect lengths and elastic moduli of the tendons, and excessive oscillations caused by an underdamped response. We are currently addressing these obstacles by redesigning the finger, and by using a mathematical model to optimize the static and dynamic characteristics of the throwing arm. We will then be able to measure the full throwing potential of our model and compare it to other throwing mechanisms, to ultimately prove or disprove our hypothesis about human throwing. |

Design

SEARCH Center air quality monitor

Jonathan Chang, Genevieve Fowler, Mieke Scherpbier, and Patrick Wilczynski

Adviser: Professor Drew Gentner, Chemical and Environmental Engineering

The SEARCH Center air quality monitors are two different monitor designs, one stationary and one portable, which contain sensors to collect research grade data of common air pollutants. Both monitors measure temperature, humidity, particulate matter, nitrogen oxides, carbon monoxide, methane, ozone, and carbon dioxide. The stationary monitor includes an additional sulfur dioxide sensor. The design is separated into two subsystems: the physical housing and the electronics. The physical housing of both monitors is constructed from a combination of acrylic and ABS plastic. The airtight and waterproof outer casing was constructed out of laser cut acrylic, glued together, and sealed with silicone sealant. Adhesive-backed copper foil was then added to the internal surface to provide electromagnetic shielding for the electronics. The internal airflow manifold components, which form an airtight chamber that houses the sensors, were 3D printed out of ABS plastic. The current system uses one printed circuit board (PCB) per sensor for the sensor itself and processing electronics. We have successfully shown changes in data output correspond as expected with changes in pollutant levels for a number of the boards, and going forward will continue to validate their functionality using our specially designed testing chamber. We will edit the design so that the data acquisition and processing electronics for all sensors sit on one PCB. The single PCB will simplify the system. Each of the sensors must be electrically connected to this board with their sensing ends in the airflow manifold at the approximate same height. The sensors can either be soldered directly to the main PCB or attached to a small raised PCB to make up for the shorter height. Sixteen bit analog-to-digital converters (ADCs) are used to convert the signal from the sensor to a digital signal. The boards have been designed so that the ADCs are as close to the sensor output as possible to minimize noise. The ADC output is communicated using I2C to the Arduino, which sits on a third PCB. This PCB also includes a battery management circuit, SD card memory slot, and a cellular data chip. As the Arduino collects the data from the ADCs, it will send it to an external server via the cell chip. This data will then be used by researchers to develop a real-time map of pollution levels across the area over which the monitors are distributed. |

Simulated body for central venous catheter placement device

Jonathan Dorsch

Adviser: Professor Steven Tommasini, Orthopedics and Rehabilitation and Biomedical Engineering

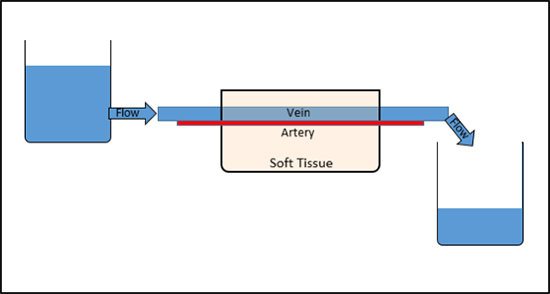

Along with two undergraduates and a resident at the medical school, we are working to create a device to improve the current method of performing central venous catheter (CVC) placement. CVC placement is a surgical technique during which physicians place a small tube within the body to gain access to the venous system. In order to improve upon current prototypes of our device and to gain more useful feedback from physicians with whom we interact, we aimed to create a more realistic model to simulate the human body in a CVC placement procedure. We have been successful in planning a model which integrates both the soft tissue surrounding the target vein as well as the circulation found within the human body. Tested independent of the soft tissue portion of the simulator, the circulation system provided proper hemodynamic conditions (accurately recreates the conditions produced by the heart in a human body). The process of creating a model for simulation of the procedure has already begun to influence aspects of the design. By continuing to create and refine the simulator, we hope to improve the quality of the device which will lead to better care for patients in need of CVC placement. Along with two undergraduates and a resident at the medical school, we are working to create a device to improve the current method of performing central venous catheter (CVC) placement. CVC placement is a surgical technique during which physicians place a small tube within the body to gain access to the venous system. In order to improve upon current prototypes of our device and to gain more useful feedback from physicians with whom we interact, we aimed to create a more realistic model to simulate the human body in a CVC placement procedure. We have been successful in planning a model which integrates both the soft tissue surrounding the target vein as well as the circulation found within the human body. Tested independent of the soft tissue portion of the simulator, the circulation system provided proper hemodynamic conditions (accurately recreates the conditions produced by the heart in a human body). The process of creating a model for simulation of the procedure has already begun to influence aspects of the design. By continuing to create and refine the simulator, we hope to improve the quality of the device which will lead to better care for patients in need of CVC placement. |

Miniaturized and low-cost VOC sensor

Evan Doyle

Adviser: Professor Drew Gentner, Chemical and Environmental Engineering

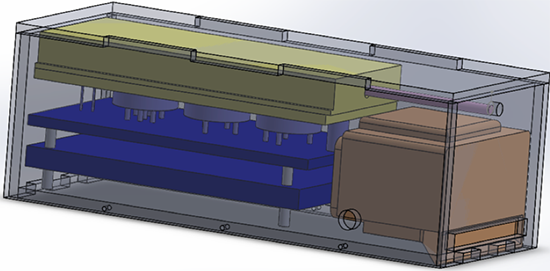

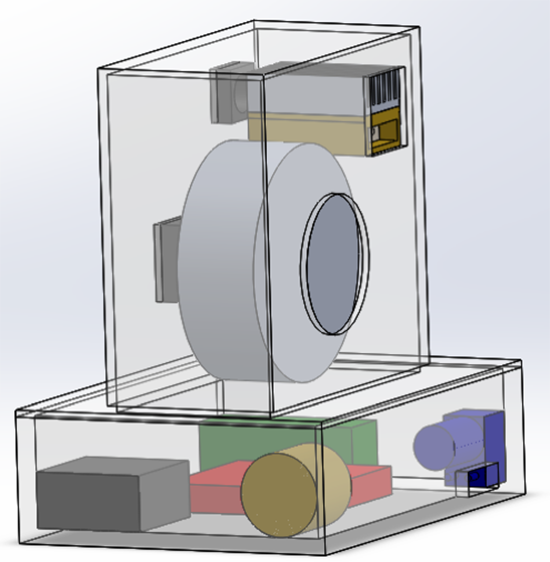

This project involves designing and prototyping an air quality monitor to detect volatile organic compounds, or VOCs. The primary goal for the semester is to make a sensor that is around the size of a shoebox, which could be widely deployable due to small size and low cost. This would be approached by first using a computer-aided design program to model the components and assembly of the sensor, and then creating a physical model based on that. In order to accomplish this, we have created a Solidworks 3D computer model of a sensor 8”X8”X6” (see the image), which incorporates the necessary chemical measurement, heating, and processing elements to measure VOCs in a field setting. This model was originally designed to be built with a frame made entirely from acrylic, but due to the high temperatures reached by some components, aluminum will be used to house heating elements. Additionally, printed circuit boards have been designed to interface with the sensor components, and will be incorporated into the system when the final prototype has been built, along with a power distribution system and control computer. This project involves designing and prototyping an air quality monitor to detect volatile organic compounds, or VOCs. The primary goal for the semester is to make a sensor that is around the size of a shoebox, which could be widely deployable due to small size and low cost. This would be approached by first using a computer-aided design program to model the components and assembly of the sensor, and then creating a physical model based on that. In order to accomplish this, we have created a Solidworks 3D computer model of a sensor 8”X8”X6” (see the image), which incorporates the necessary chemical measurement, heating, and processing elements to measure VOCs in a field setting. This model was originally designed to be built with a frame made entirely from acrylic, but due to the high temperatures reached by some components, aluminum will be used to house heating elements. Additionally, printed circuit boards have been designed to interface with the sensor components, and will be incorporated into the system when the final prototype has been built, along with a power distribution system and control computer. |

Optical hemoglobin meter

Russell Egly

Adviser: Professor Douglas Rothman, Biomedical Engineering and Diagnostic Radiology

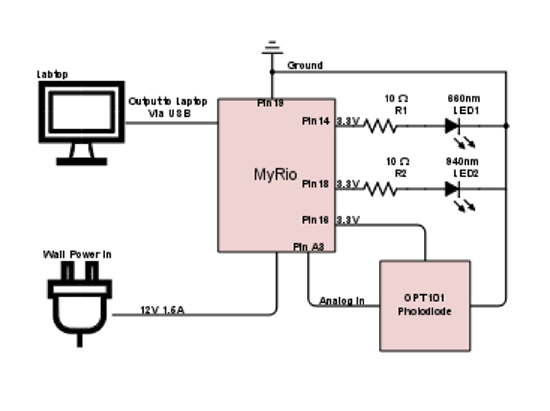

It is immensely important for people to have access to a portable, non-invasive device for measuring blood hemoglobin concentration. We designed a device that uses two light emitting diodes with a photodiode in a finger splint and a National Instruments myRio microcontroller deck to measure this concentration. The circuit hardware has been assembled and the device has been used to measure a user’s pulse. The circuit diagram shows the final layout of the device and how the diodes interface with the microcontroller and a desktop. The lights and photodiode are currently housed in a finger splint and the signal is taken through the finger sideways as this has yielded the signal with the best signal to noise ratio compared to a light signal transmitted vertically through the finger or reflected off the bone in the finger. We also found that the two wavelengths of light generate different signals and in the remaining time in the semester we will be working to correlate the ratio of these signals to actual blood hemoglobin concentration. We also implemented resistors to guarantee that the power being emitted by the lights complies with Food and Drug Administration regulations (< 3 W/cm2). It is immensely important for people to have access to a portable, non-invasive device for measuring blood hemoglobin concentration. We designed a device that uses two light emitting diodes with a photodiode in a finger splint and a National Instruments myRio microcontroller deck to measure this concentration. The circuit hardware has been assembled and the device has been used to measure a user’s pulse. The circuit diagram shows the final layout of the device and how the diodes interface with the microcontroller and a desktop. The lights and photodiode are currently housed in a finger splint and the signal is taken through the finger sideways as this has yielded the signal with the best signal to noise ratio compared to a light signal transmitted vertically through the finger or reflected off the bone in the finger. We also found that the two wavelengths of light generate different signals and in the remaining time in the semester we will be working to correlate the ratio of these signals to actual blood hemoglobin concentration. We also implemented resistors to guarantee that the power being emitted by the lights complies with Food and Drug Administration regulations (< 3 W/cm2). |

Waste allocation load lifter – Yale class

Jonathan Karp, Amy Rockwood, and Jordan Sabin

Adviser: Professor Corey O’Hern, Mechanical Engineering and Materials Science

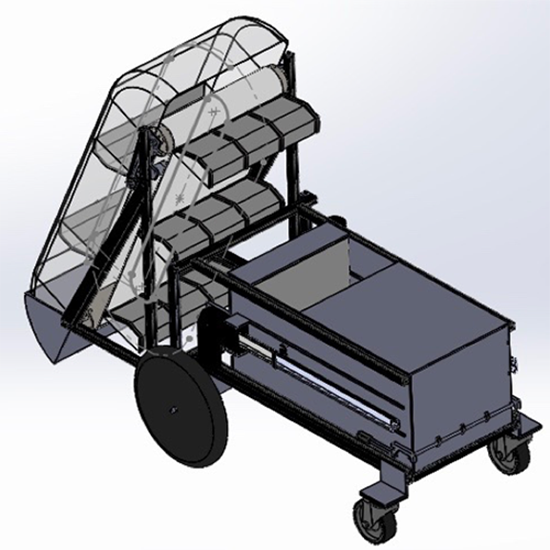

The purpose of this project is to develop an improved method for collecting trash in parking lots following tailgates. Current best practices rely on manual labor, making them costly and inefficient. We aim to disrupt this paradigm by developing a semi-autonomous electro-mechanical trash collector. Below we highlight the detailed design and engineering work completed on the system to date. The device can be broken down into three distinct subsystems: (1) a collection system to pick up pieces of rubbish, (2) a compaction system to reduce the bulk volume of waste, and (3) an overarching control subsystem. The design of the collection subsystem focused on the development of a scooped conveyor belt system to allow for the semi-continuous collection of trash. Difficulty with the tendency of cylindrical objects to roll away from scoop mechanisms required the implementation of a backstop. This backstop rides along the ground and is attached to a suspension to allow for movement over uneven terrain. A significant focus was placed on the development of 1/16th inch polycarbonate scoops rigid enough to hold 4 kg of trash and yet flexible enough to bend over uneven terrain. The design of the compaction system centered on the need to exert approximately 2,000 lbf to compress trash into a solid cube. Cost considerations, and a desire for equal force distribution across the plate area, resulted in the development of a compaction system with two separate track actuators, each capable of producing 900 lbf. The compaction system also serves as a disposal mechanism, pushing compacted blocks of trash out of the hinged front panel. The forces exerted on this hinge and lock assembly drove the development of an in-house designed mechanism based on those used in dump trucks. Finally, the design of the control subsystem focused on the realization of long-range remote control, the effective control of drive and secondary motors, and the implementation of several sensor feedback loops. Long-range remote control will be implemented over radio waves. Pulse-width modulation will be utilized to allow for differential skid turning, and an array of sensors, including power resistors and string potentiometers, will provide feedback on force exerted and the volume of trash compacted. In the coming weeks, the manufacture, assembly, and integration of the systems outlined above will result in a robot capable of clearing parking lots of trash and depositing the collected waste in easily disposed of compacted blocks. The purpose of this project is to develop an improved method for collecting trash in parking lots following tailgates. Current best practices rely on manual labor, making them costly and inefficient. We aim to disrupt this paradigm by developing a semi-autonomous electro-mechanical trash collector. Below we highlight the detailed design and engineering work completed on the system to date. The device can be broken down into three distinct subsystems: (1) a collection system to pick up pieces of rubbish, (2) a compaction system to reduce the bulk volume of waste, and (3) an overarching control subsystem. The design of the collection subsystem focused on the development of a scooped conveyor belt system to allow for the semi-continuous collection of trash. Difficulty with the tendency of cylindrical objects to roll away from scoop mechanisms required the implementation of a backstop. This backstop rides along the ground and is attached to a suspension to allow for movement over uneven terrain. A significant focus was placed on the development of 1/16th inch polycarbonate scoops rigid enough to hold 4 kg of trash and yet flexible enough to bend over uneven terrain. The design of the compaction system centered on the need to exert approximately 2,000 lbf to compress trash into a solid cube. Cost considerations, and a desire for equal force distribution across the plate area, resulted in the development of a compaction system with two separate track actuators, each capable of producing 900 lbf. The compaction system also serves as a disposal mechanism, pushing compacted blocks of trash out of the hinged front panel. The forces exerted on this hinge and lock assembly drove the development of an in-house designed mechanism based on those used in dump trucks. Finally, the design of the control subsystem focused on the realization of long-range remote control, the effective control of drive and secondary motors, and the implementation of several sensor feedback loops. Long-range remote control will be implemented over radio waves. Pulse-width modulation will be utilized to allow for differential skid turning, and an array of sensors, including power resistors and string potentiometers, will provide feedback on force exerted and the volume of trash compacted. In the coming weeks, the manufacture, assembly, and integration of the systems outlined above will result in a robot capable of clearing parking lots of trash and depositing the collected waste in easily disposed of compacted blocks. |

Materials

Reusable bulk metallic glass molds for small parts

Kori Baij

Adviser: Professor Jan Schroers, Mechanical Engineering and Materials Science

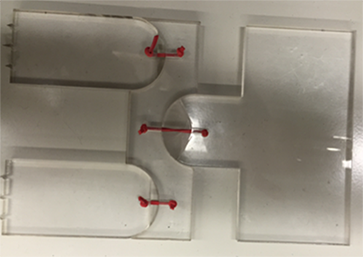

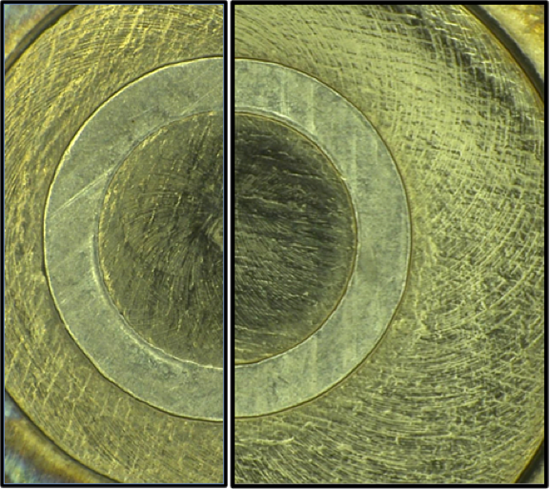

The manufacture of small metal parts is a process that could be streamlined by the introduction of reusable molds. Currently, small parts are only mass-produced through machining, and small bulk metallic glass parts shaped by thermoplastic formation utilize single-use silicon wafer molds. This research focuses on the factors that determine the closeness of the mold to the part we are replicating, namely the alloy of the mold material, formation environment (heat, pressure, length of time), and the size of the well holding the part. In the image, we see side-by-side two steel washers embedded in the mold material, the right in a larger well (200% of the washer’s outer diameter), and the left in a smaller one (150% of the diameter). We found that the larger apertures produced molds that formed more tightly to the part to be reproduced. The next set of trials will test enclosures that are 300% the washer’s outer diameter to test the relationship between enclosure size and the gap between mold and part. Future avenues of research include the factors involved in part release and the lifetime of such molds over many stress cycles. The manufacture of small metal parts is a process that could be streamlined by the introduction of reusable molds. Currently, small parts are only mass-produced through machining, and small bulk metallic glass parts shaped by thermoplastic formation utilize single-use silicon wafer molds. This research focuses on the factors that determine the closeness of the mold to the part we are replicating, namely the alloy of the mold material, formation environment (heat, pressure, length of time), and the size of the well holding the part. In the image, we see side-by-side two steel washers embedded in the mold material, the right in a larger well (200% of the washer’s outer diameter), and the left in a smaller one (150% of the diameter). We found that the larger apertures produced molds that formed more tightly to the part to be reproduced. The next set of trials will test enclosures that are 300% the washer’s outer diameter to test the relationship between enclosure size and the gap between mold and part. Future avenues of research include the factors involved in part release and the lifetime of such molds over many stress cycles. |

Effect of thermal cycling on the fracture toughness of bulk metallic glasses

Matthew Blake Knuth

Adviser: Professor Jan Schroers, Mechanical Engineering and Materials Science

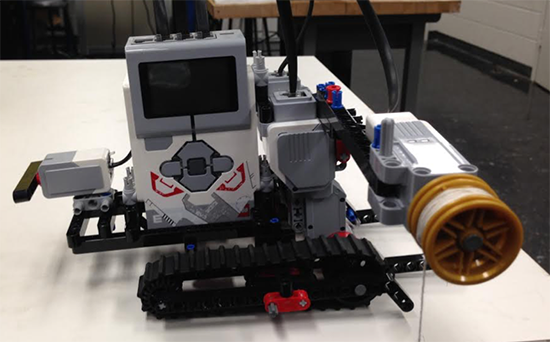

This research project is focused on investigating the effect of cyclical cooling on bulk metallic glass samples. Bulk metallic glasses are metal alloys with an amorphous microstructure. In our experiment, metallic glasses are cycled between thermal reservoirs containing liquid nitrogen and lukewarm water. We are examining the impact of 5, 50, and 500 cycles. We built a robot out of repurposed LEGO parts and electronics to reliably perform the long experiments. The three-actuator robot functions by first lowering samples on spooled string into liquid nitrogen for 1 minute, pulling them out and rolling forward 8 inches, lowering them into water for 1 minute, and then rolling back until a force sensor notifies it that it has reached its home position. The material properties of the experimental samples were tested through tensile testing. Due to different local coefficients of thermal expansion within our samples, we predict that increasing the number of thermal cycles the samples undergo will result in increased fracture toughnesses. This research project is focused on investigating the effect of cyclical cooling on bulk metallic glass samples. Bulk metallic glasses are metal alloys with an amorphous microstructure. In our experiment, metallic glasses are cycled between thermal reservoirs containing liquid nitrogen and lukewarm water. We are examining the impact of 5, 50, and 500 cycles. We built a robot out of repurposed LEGO parts and electronics to reliably perform the long experiments. The three-actuator robot functions by first lowering samples on spooled string into liquid nitrogen for 1 minute, pulling them out and rolling forward 8 inches, lowering them into water for 1 minute, and then rolling back until a force sensor notifies it that it has reached its home position. The material properties of the experimental samples were tested through tensile testing. Due to different local coefficients of thermal expansion within our samples, we predict that increasing the number of thermal cycles the samples undergo will result in increased fracture toughnesses. |

Bulk metallic glasses in surgical needle design

Erik Tharp

Adviser: Professor Jan Schroers, Mechanical Engineering and Materials Science

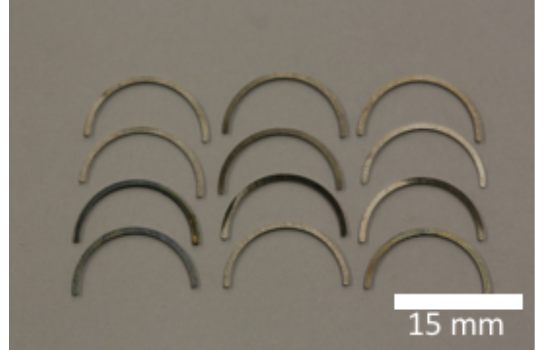

The focus of this project was to explore bulk metallic glasses (BMGs) as a potential candidate material for the manufacture of surgical needles in the hopes of significantly improved needle performance. Due to their high strength and hardness, BMGs could provide a more resilient cutting tool by comparison to stainless steel needles. Our needle prototypes were modelled after a general purpose needle design produced by Medtronic and will be tested for strength via their bend moment. To determine if the properties of BMGs made for a better cutting needle, the prototypes will be tested against existing steel needles for penetrative force through a standard test medium over multiple penetrations. Testing is ongoing, but we anticipate that the needles will resist a higher load in the bend moment test and maintain consistently lower penetrative forces over the course of testing, indicating that the use of BMGs improved the resilience of the needles. These stronger prototypes that are less prone to dulling of the tip would provide solid evidence that BMGs are a promising material for use in the production of surgical needles, with particular utility in the design of ophthalmic and microsurgery needles. The focus of this project was to explore bulk metallic glasses (BMGs) as a potential candidate material for the manufacture of surgical needles in the hopes of significantly improved needle performance. Due to their high strength and hardness, BMGs could provide a more resilient cutting tool by comparison to stainless steel needles. Our needle prototypes were modelled after a general purpose needle design produced by Medtronic and will be tested for strength via their bend moment. To determine if the properties of BMGs made for a better cutting needle, the prototypes will be tested against existing steel needles for penetrative force through a standard test medium over multiple penetrations. Testing is ongoing, but we anticipate that the needles will resist a higher load in the bend moment test and maintain consistently lower penetrative forces over the course of testing, indicating that the use of BMGs improved the resilience of the needles. These stronger prototypes that are less prone to dulling of the tip would provide solid evidence that BMGs are a promising material for use in the production of surgical needles, with particular utility in the design of ophthalmic and microsurgery needles. |

Mathematical Modeling

Recursive derivations of equations of motion for kinematic chains

Jeffrey Gau

Adviser: Professor Madhusudhan Venkadesan, Mechanical Engineering and Materials Science

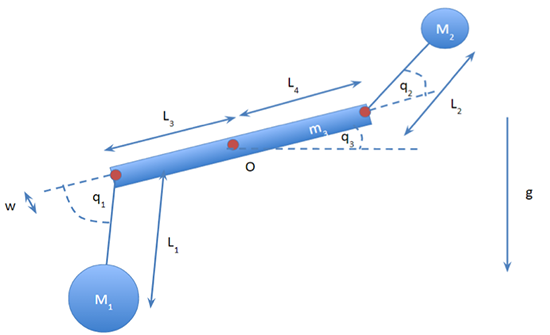

It can be useful to model complex mechanical systems as kinematic chains. However, solving the equations of motion for such chains can be computationally expensive. Implementing a recursive solution to this problem will allow us to develop an efficient and accurate program. Such an approach involves propagating the states of each link along the chain, thereby reducing the number of calculations required. We have already developed a program to non-recursively solve the equations of motion and conduct a sensitivity analysis on two types of kinematic chains: simple and triple pendulums. The figure shows the coordinates used to define the triple pendulum, which is fixed to the world at point O. We analyzed the first singular value of the sensitivity matrix for both systems, because these values provide a measure of the overall sensitivity of a system. Using the simple pendulum, we verified the results generated by the program against exact solutions solved algebraically. We then used the triple pendulum case to validate that the program and MATLAB’s ordinary differential equation solver can accurately calculate the sensitivity for a chaotic system. We are now in the process of implementing recursion to improve the efficiency of our program. It can be useful to model complex mechanical systems as kinematic chains. However, solving the equations of motion for such chains can be computationally expensive. Implementing a recursive solution to this problem will allow us to develop an efficient and accurate program. Such an approach involves propagating the states of each link along the chain, thereby reducing the number of calculations required. We have already developed a program to non-recursively solve the equations of motion and conduct a sensitivity analysis on two types of kinematic chains: simple and triple pendulums. The figure shows the coordinates used to define the triple pendulum, which is fixed to the world at point O. We analyzed the first singular value of the sensitivity matrix for both systems, because these values provide a measure of the overall sensitivity of a system. Using the simple pendulum, we verified the results generated by the program against exact solutions solved algebraically. We then used the triple pendulum case to validate that the program and MATLAB’s ordinary differential equation solver can accurately calculate the sensitivity for a chaotic system. We are now in the process of implementing recursion to improve the efficiency of our program. |

Creating a heat transfer model for sizing and designing thermoGreenWalls based on geographic location

Astrid Sardiñas

Advisers: Professor James Axley, Architecture and Forestry & Environmental Studies, and Professor Alexander Felson, Architecture and Forestry & Environmental Studies

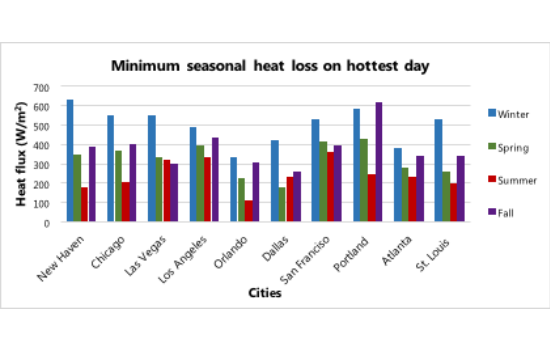

The Urban Ecology and Design Laboratory is working on developing a sustainable active heat rejection technology called a thermoGreenWall system. ThermoGreenWalls reject heat through evaporation and convection like cooling towers, but resemble passive green walls in appearance and their potential environmental benefits. By utilizing weather data for the typical meteorological year from 1991 to 2005, we developed a macroscopic heat transfer model of the thermoGreenWalls based on their regional and site-specific placement. Our model shows that the thermoGreenWalls perform the worst during the summer months, while rejecting the most heat during the winter. Furthermore, the thermoGreenWalls seem to perform best in hot, dry cities like Las Vegas and Los Angeles during the summer months, followed by marine cities on the west coast like San Francisco and Portland, as shown in the figure. These heat rejection potentials allow for easy sizing of the thermoGreenWalls depending on the cooling load. Our model also showed that much higher heat rejection rates could be achieved by increasing the wind speed at the wall, and by keeping its view unobstructed to allow for long wave radiation loss. These considerations can be helpful when deciding the placement of thermoGreenWalls in order to maximize their performance. The Urban Ecology and Design Laboratory is working on developing a sustainable active heat rejection technology called a thermoGreenWall system. ThermoGreenWalls reject heat through evaporation and convection like cooling towers, but resemble passive green walls in appearance and their potential environmental benefits. By utilizing weather data for the typical meteorological year from 1991 to 2005, we developed a macroscopic heat transfer model of the thermoGreenWalls based on their regional and site-specific placement. Our model shows that the thermoGreenWalls perform the worst during the summer months, while rejecting the most heat during the winter. Furthermore, the thermoGreenWalls seem to perform best in hot, dry cities like Las Vegas and Los Angeles during the summer months, followed by marine cities on the west coast like San Francisco and Portland, as shown in the figure. These heat rejection potentials allow for easy sizing of the thermoGreenWalls depending on the cooling load. Our model also showed that much higher heat rejection rates could be achieved by increasing the wind speed at the wall, and by keeping its view unobstructed to allow for long wave radiation loss. These considerations can be helpful when deciding the placement of thermoGreenWalls in order to maximize their performance. |

Numerical Modeling

Modeling granular avalanching in a 2D rotating drum

Hans Kassier

Adviser: Professor Corey O'Hern, Mechanical Engineering and Materials Science

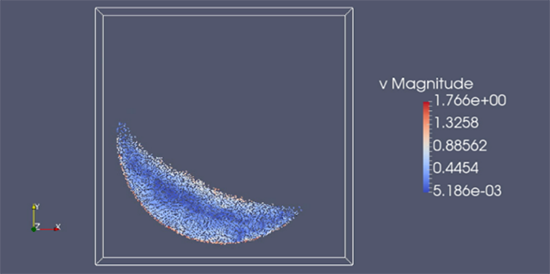

An avalanche is a sudden change in the gravitational potential energy of a granular system. Collaborators of Professor O’Hern investigated the distribution of avalanche size for a granular system in a rotating drum and found that avalanche size followed a power law distribution. We worked this semester to create a computer model that would extend these results, since time constraints limited their experiment to a single material. After constructing the model, we visualized the movement of the particles during drum rotation to check for proper particle behavior. As illustrated by the velocity distribution of the particles in the image, the model achieved mixing. To ensure consistency across trials, we required that the particles had reached equilibrium (i.e., the particles had settled) after insertion but before the drum started rotating. We therefore augmented the code to calculate kinetic energy of the system and used this to determine when the system had settled. Analysis of a dozen preliminary trials showed that the avalanche size of the model system followed a rough power law distribution. Calibration of the model will continue until our distributions match the experimental results. The model will then be used to determine the avalanche characteristics of different systems. An avalanche is a sudden change in the gravitational potential energy of a granular system. Collaborators of Professor O’Hern investigated the distribution of avalanche size for a granular system in a rotating drum and found that avalanche size followed a power law distribution. We worked this semester to create a computer model that would extend these results, since time constraints limited their experiment to a single material. After constructing the model, we visualized the movement of the particles during drum rotation to check for proper particle behavior. As illustrated by the velocity distribution of the particles in the image, the model achieved mixing. To ensure consistency across trials, we required that the particles had reached equilibrium (i.e., the particles had settled) after insertion but before the drum started rotating. We therefore augmented the code to calculate kinetic energy of the system and used this to determine when the system had settled. Analysis of a dozen preliminary trials showed that the avalanche size of the model system followed a rough power law distribution. Calibration of the model will continue until our distributions match the experimental results. The model will then be used to determine the avalanche characteristics of different systems. |