MENG 471 Projects - Fall 2021

In MENG 471, students work on independent projects that cover a wide range of topics, from traditional mechanical engineering topics (e.g., mechanical device design, fluid flow, and materials analysis) to interdisciplinary topics at the interface between mechanical engineering and other branches of engineering such as biomedical, chemical, electrical, or environmental engineering. Under the supervision of faculty advisers, students investigate physical phenomena through experimental measurement and/or numerical simulation, and they design and construct functioning prototypes to solve engineering problems. The majority of the faculty advisers come from within the mechanical engineering department, with the remaining advisers distributed across the University (and occasionally outside the University). Funding for projects is generously provided by the Yale SEAS Dean's Office and, in some cases, through the faculty advisers. The students were asked to write the following short summaries two-thirds of the way through the semester, when they still had a few weeks to go on their projects. All projects are represented here, except for those that cannot be publicized due to information of a proprietary nature.

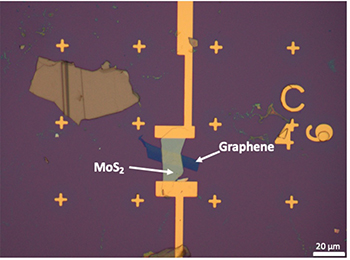

Effect of a graphene-MoS2 heterointerface on the lithium intercalation-induced phase transition

Maria Bambrick-Santoyo

Co-advisers: Dr. Mengjing Wang and Prof. Judy Cha, Mechanical Engineering & Materials Science

The two-dimensional transition metal dichalcogenides (2D TMDCs) are a group of molecules that are promising for a wide range of applications, including energy storage, catalysis, and memory. Specifically, through intercalation — the insertion of ions (in this case, lithium) in the gaps between the layers — a reversible phase change can be induced. For example, molybdenum disulfide (MoS2) is semiconducting in ambient conditions but can transition to a metallic phase. We are studying a flake of MoS2 with a narrow strip of graphene placed on top. Past research suggests that the strip of graphene above the MoS2 flake should suppress the phase transition, but this specific geometry has not previously been studied. We modified the current intercalation cell design in Dr. Cha’s lab to include an additional gate terminal that would perform the necessary measurements of current and voltage. Our future experiments will enable us to observe how the phase transition progresses. If the graphene-covered region is protected from a phase transition, the result will be a flake that is patterned metallic-semiconducting-metallic. The results of this work could have direct implications for transistors and more.

The two-dimensional transition metal dichalcogenides (2D TMDCs) are a group of molecules that are promising for a wide range of applications, including energy storage, catalysis, and memory. Specifically, through intercalation — the insertion of ions (in this case, lithium) in the gaps between the layers — a reversible phase change can be induced. For example, molybdenum disulfide (MoS2) is semiconducting in ambient conditions but can transition to a metallic phase. We are studying a flake of MoS2 with a narrow strip of graphene placed on top. Past research suggests that the strip of graphene above the MoS2 flake should suppress the phase transition, but this specific geometry has not previously been studied. We modified the current intercalation cell design in Dr. Cha’s lab to include an additional gate terminal that would perform the necessary measurements of current and voltage. Our future experiments will enable us to observe how the phase transition progresses. If the graphene-covered region is protected from a phase transition, the result will be a flake that is patterned metallic-semiconducting-metallic. The results of this work could have direct implications for transistors and more.

Design of a device for measuring ground forces of mudskippers

Cassie Clement

Adviser: Prof. Madhusudhan Venkadesan, Mechanical Engineering & Materials Science

Mudskippers, also referred to as “walking fish,” have evolved the ability to live out of water for days. They are small, ranging from 2.75 inches to 9.75 inches in length. In order to understand how they move on land, and possibly gain a better understanding of the evolution of terrestrial locomotion in vertebrates, the ground forces of these walking fish must be measured. To do so, an approach is under development to estimate ground forces using the deformation patterns produced when walking across an elastic membrane. We did research and performed calculations in MATLAB to determine the desired type and thickness of material, learning that polyester material of thickness 0.0005” to 0.001” was ideal. Trade-offs arise in available materials between their thickness, Young’s modulus, and reflectivity. We have designed a prototype using a snare drum, which has lugs used to tighten the material and, therefore, limit errors caused by wrinkling and sagging. The drum head was replaced with the ideal polyester. We are currently creating tests to determine the effects of the diameter and number of lugs. Once this is done, our team can begin testing the mudskippers.

Mudskippers, also referred to as “walking fish,” have evolved the ability to live out of water for days. They are small, ranging from 2.75 inches to 9.75 inches in length. In order to understand how they move on land, and possibly gain a better understanding of the evolution of terrestrial locomotion in vertebrates, the ground forces of these walking fish must be measured. To do so, an approach is under development to estimate ground forces using the deformation patterns produced when walking across an elastic membrane. We did research and performed calculations in MATLAB to determine the desired type and thickness of material, learning that polyester material of thickness 0.0005” to 0.001” was ideal. Trade-offs arise in available materials between their thickness, Young’s modulus, and reflectivity. We have designed a prototype using a snare drum, which has lugs used to tighten the material and, therefore, limit errors caused by wrinkling and sagging. The drum head was replaced with the ideal polyester. We are currently creating tests to determine the effects of the diameter and number of lugs. Once this is done, our team can begin testing the mudskippers.

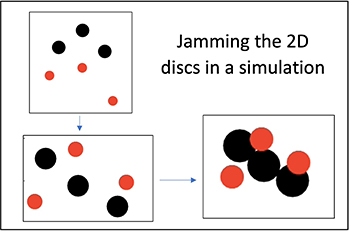

Comparing the differences in jammed packing vibrations between disconnected discs and polymers

Aliza Fisher

Adviser: Prof. Corey O'Hern, Mechanical Engineering & Materials Science

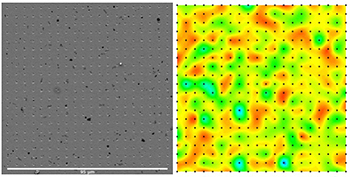

Proteins are complicated structures that are made up of sequences of amino acids which form various protein chains. In their natural state, proteins are subject to vibrations and fluctuations that affect their overall structure and properties. One way we have been able to study these effects is to create a system using computer simulations that replicate these natural vibrations. We represent protein cores using 2D discs as seen in the figure. In a molecular dynamics simulation, we can subject the particles to vibrations that depend on certain variables that we can control. Once the particles are excited, we analyze the system using C++ and MATLAB algorithms involving the Fourier transform of an autocorrelation function. In the future, we hope to finish our Fourier transform analysis for the 2D discs. We will then scale up the simulation to a more advanced system, which will have the same 2D discs, but they will be connected like beads on a string. By doing this, we will be able to analyze the differences in the density of vibrational states between the two systems and better understand the properties of protein cores at their jammed state.

Proteins are complicated structures that are made up of sequences of amino acids which form various protein chains. In their natural state, proteins are subject to vibrations and fluctuations that affect their overall structure and properties. One way we have been able to study these effects is to create a system using computer simulations that replicate these natural vibrations. We represent protein cores using 2D discs as seen in the figure. In a molecular dynamics simulation, we can subject the particles to vibrations that depend on certain variables that we can control. Once the particles are excited, we analyze the system using C++ and MATLAB algorithms involving the Fourier transform of an autocorrelation function. In the future, we hope to finish our Fourier transform analysis for the 2D discs. We will then scale up the simulation to a more advanced system, which will have the same 2D discs, but they will be connected like beads on a string. By doing this, we will be able to analyze the differences in the density of vibrational states between the two systems and better understand the properties of protein cores at their jammed state.

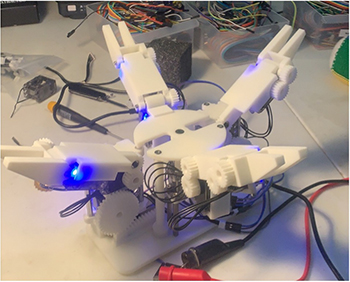

Design and construction of an energy-map optimized robotic hand

Laszlo Kopits

Advisers: Profs. Aaron Dollar and Corey O'Hern, Mechanical Engineering & Materials Science

While it is relatively simple to create a robotic hand which can grip and pick up a wide range of objects, it is much more difficult to create one which can manipulate and reorient objects without releasing them. Within the field of robotic object manipulation, there exist many different computational models that predict the motion an object given the programmed motion of a robotic hand. However, many popular models lack the robustness needed to perform in a real-world environment. A new model, known as the energy-map model, has previously been used to optimize a design for a robotic hand which can manipulate and reorient a wide variety of different objects in a 2D plane. In the current work, along with a PhD candidate in the Yale GRAB Lab, we design and construct a hand using the same technique except in the 3D space. The optimized hand has four fingers, each with two joints. One pair of fingers can rotate together around the center of the hand. The other pair can translate independently towards and away from the palm. The constructed hand has been shown manipulating a wide variety of objects. As a result, this research could increase the viability of robotic hands in real-world applications.

While it is relatively simple to create a robotic hand which can grip and pick up a wide range of objects, it is much more difficult to create one which can manipulate and reorient objects without releasing them. Within the field of robotic object manipulation, there exist many different computational models that predict the motion an object given the programmed motion of a robotic hand. However, many popular models lack the robustness needed to perform in a real-world environment. A new model, known as the energy-map model, has previously been used to optimize a design for a robotic hand which can manipulate and reorient a wide variety of different objects in a 2D plane. In the current work, along with a PhD candidate in the Yale GRAB Lab, we design and construct a hand using the same technique except in the 3D space. The optimized hand has four fingers, each with two joints. One pair of fingers can rotate together around the center of the hand. The other pair can translate independently towards and away from the palm. The constructed hand has been shown manipulating a wide variety of objects. As a result, this research could increase the viability of robotic hands in real-world applications.

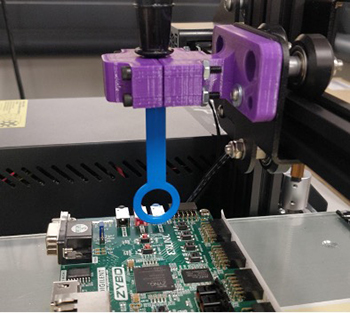

Electromagnetic scanner for detecting counterfeit electronic parts

Charlie Loitman

Adviser: Prof. Jakub Szefer, Electrical Engineering

Counterfeit electronic parts are both costly to the economy and costly to detect. Current detection methods take advantage of the fact that — due to differences in manufacturing and installation techniques — counterfeit parts release electromagnetic radiation at different rates than their genuine counterparts. Comparing measured radiation values at each location above a test part to those of a control part allows easy identification of fakes. However, existing solutions use expensive equipment, preventing widespread adoption and testing. To combat the proliferation of counterfeits, we are attempting to replicate this process at a fraction of the cost. The most expensive component is a robotic arm that moves a probe. We have 3D printed mounts to replace the extruder head of a printer to allow similar functionality, as 3D printers can move to precise locations at any point above a plane. Attaching radiation probes to these mounts and writing code to allow autonomous testing should work at least as well as current solutions. By using only readily available or craftable parts and open-sourcing code and instructions, we will make it easier for others to conduct similar tests and hopefully reduce the impact of counterfeit parts.

Counterfeit electronic parts are both costly to the economy and costly to detect. Current detection methods take advantage of the fact that — due to differences in manufacturing and installation techniques — counterfeit parts release electromagnetic radiation at different rates than their genuine counterparts. Comparing measured radiation values at each location above a test part to those of a control part allows easy identification of fakes. However, existing solutions use expensive equipment, preventing widespread adoption and testing. To combat the proliferation of counterfeits, we are attempting to replicate this process at a fraction of the cost. The most expensive component is a robotic arm that moves a probe. We have 3D printed mounts to replace the extruder head of a printer to allow similar functionality, as 3D printers can move to precise locations at any point above a plane. Attaching radiation probes to these mounts and writing code to allow autonomous testing should work at least as well as current solutions. By using only readily available or craftable parts and open-sourcing code and instructions, we will make it easier for others to conduct similar tests and hopefully reduce the impact of counterfeit parts.

Modifying the design of an electronic acoustic bass instrument

Baltazar Lora

Co-advisers: Profs. Konrad Kaczmarek, School of Music, and Corey O’Hern, Mechanical Engineering & Materials Science

As an avid concert musician and producer, my aim this semester has been to work in the vein of electronic instrument design to some capacity. Thus, we are modifying an electronic upright bass instrument designed by Prof. Kaczmarek and Prof. Lawrence Wilen. The instrument is a long, narrow piece of wood with a soft membrane potentiometer which tracks which notes are being held on the fretboard. A physical bow, concealing a BNO055 sensor, tracks the motion and orientation of the player's right hand. This dictates which string is being played and how it is being played. At the core of the instrument is a Teensy Arduino which allows the instrument to function as a Musical Instrument Digital Interface (MIDI). This semester’s work consists of implementing a time-of-flight sensor to enhance finger tracking capabilities, including a multi-LED strip in the bow to communicate which string is being played and cut down on excess wiring. It also consists of recording and organizing data to ultimately submit the project and its constituent files to GitHub. Ultimately, our goal is to modify the design to a new format which would allow for use of the instrument in live concert and in music production settings.

As an avid concert musician and producer, my aim this semester has been to work in the vein of electronic instrument design to some capacity. Thus, we are modifying an electronic upright bass instrument designed by Prof. Kaczmarek and Prof. Lawrence Wilen. The instrument is a long, narrow piece of wood with a soft membrane potentiometer which tracks which notes are being held on the fretboard. A physical bow, concealing a BNO055 sensor, tracks the motion and orientation of the player's right hand. This dictates which string is being played and how it is being played. At the core of the instrument is a Teensy Arduino which allows the instrument to function as a Musical Instrument Digital Interface (MIDI). This semester’s work consists of implementing a time-of-flight sensor to enhance finger tracking capabilities, including a multi-LED strip in the bow to communicate which string is being played and cut down on excess wiring. It also consists of recording and organizing data to ultimately submit the project and its constituent files to GitHub. Ultimately, our goal is to modify the design to a new format which would allow for use of the instrument in live concert and in music production settings.

Nanomechanical testing of 3D-printed ceramics

Bryan Regan

Co-advisers: Dr. Amit Datye and Prof. Udo Schwarz, Mechanical Engineering & Materials Science

3D printing high-strength ceramics is a difficult process to conduct reliably. Current methods of printing ceramic parts involve extruding a slurry made of ceramic particles and a binder in order to build the part layer by layer, much like conventional 3D printers. However, after the ceramic part has been constructed, it must be heated in a furnace, which can introduce defects and non-uniformities. Ceramics are thermal insulators, which means the material will both heat and cool at different rates. As a result, different sections of the part may not have the same material properties. In our research, we have validated the uniformity of the material properties for 3D-printed alumina and zirconia samples using nanoindentation. Nanoindentation is a process where the size of an indentation made in a material is used to determine various material properties. Hundreds of indentations were made in multiple regions of the sample in order to verify that the modulus and hardness were consistent throughout the material. Ultimately, we have reported our findings to Lithoz, a company pioneering 3D-printing techniques, in order to help them refine their printing methods.

3D printing high-strength ceramics is a difficult process to conduct reliably. Current methods of printing ceramic parts involve extruding a slurry made of ceramic particles and a binder in order to build the part layer by layer, much like conventional 3D printers. However, after the ceramic part has been constructed, it must be heated in a furnace, which can introduce defects and non-uniformities. Ceramics are thermal insulators, which means the material will both heat and cool at different rates. As a result, different sections of the part may not have the same material properties. In our research, we have validated the uniformity of the material properties for 3D-printed alumina and zirconia samples using nanoindentation. Nanoindentation is a process where the size of an indentation made in a material is used to determine various material properties. Hundreds of indentations were made in multiple regions of the sample in order to verify that the modulus and hardness were consistent throughout the material. Ultimately, we have reported our findings to Lithoz, a company pioneering 3D-printing techniques, in order to help them refine their printing methods.

Design of a leak-reducing nozzle for concrete 3D printing

Simon Ta

Co-advisers: Dr. Joran Booth and Prof. Corey O’Hern, Mechanical Engineering & Materials Science

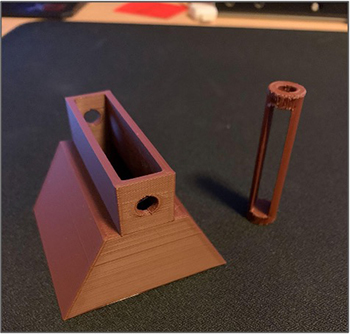

Concrete 3D printing is a growing industry that aims to 3D print homes and buildings autonomously from the ground up. SQ4D is a concrete 3D-printing company that has constructed the first commercially available concrete 3D-printed home. Their printer is unique because it can also print the foundation of the house, which dramatically reduces construction time. However, SQ4D’s printer at times leaks concrete while the 3D printer is not actively printing material. To combat this problem, we are designing a solution that can be implemented into SQ4D’s nozzle to prevent this leakage of concrete. We began with preliminary designs, which were 3D printed with plastic and tested using hand printing techniques. From there, we refined our design to produce cleaner prints with tighter tolerances and considered the best materials to manufacture our final prototypes. We are in the process of machining, assembling, and testing the final prototype of the nozzle anti-leakage design. Including this system onto SQ4D’s existing nozzle may solve the issue of extraneous concrete spilling onto the print layers and prevent messes that could create printing obstructions.

Concrete 3D printing is a growing industry that aims to 3D print homes and buildings autonomously from the ground up. SQ4D is a concrete 3D-printing company that has constructed the first commercially available concrete 3D-printed home. Their printer is unique because it can also print the foundation of the house, which dramatically reduces construction time. However, SQ4D’s printer at times leaks concrete while the 3D printer is not actively printing material. To combat this problem, we are designing a solution that can be implemented into SQ4D’s nozzle to prevent this leakage of concrete. We began with preliminary designs, which were 3D printed with plastic and tested using hand printing techniques. From there, we refined our design to produce cleaner prints with tighter tolerances and considered the best materials to manufacture our final prototypes. We are in the process of machining, assembling, and testing the final prototype of the nozzle anti-leakage design. Including this system onto SQ4D’s existing nozzle may solve the issue of extraneous concrete spilling onto the print layers and prevent messes that could create printing obstructions.