Switching from Robots to Ventilators: How a Class Responds to Covid-19

When students in Mechatronics (MENG 390) left for spring break, they expected to begin work on two-wheeled balancing robots upon their return. When classes resumed, though, their end-of the-semester class project had changed to exploring new ventilator designs.

The change, said Madhusudhan Venkadesan, came shortly after it was announced that classes would move online to slow the spread of the COVID-19 outbreak.

The change, said Madhusudhan Venkadesan, came shortly after it was announced that classes would move online to slow the spread of the COVID-19 outbreak.

“We joined the boat of people who were scrambling to wrap their heads around these changes to our lives,” said Venkadesan, assistant professor of mechanical engineering and materials science. “I find it hard to believe that one would feel motivated to get a two-wheeled robot balancing while we’re being inundated by the COVID-19 virus.”

The change was also driven in part by logistics.

“If we tried to transport the lab into homes by shipping kits, it simply wouldn’t match the type of learning that a lab provides,” he said. “On the other hand, the purpose of a class like Mechatronics is to take a deeper dive into how control systems work, how we can automate mechanical systems using microcontrollers, and so on. And this seemed like a confluence of need, and the goals of this class.”

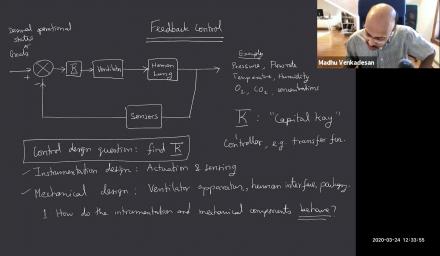

On the surface, the two projects may seem very different, but there’s a lot of overlap in the mechanical principles behind each. The students can take the things they’ve learned already this semester and apply them to several questions related to ventilator design. For instance, what is the process for designing a control system, what pressures are OK for the human lung, what is the right flow rate, and how can you know if it’s potentially causing harm?

“The students are well-situated to think about how one designs a control system,” Venkadesan said. “These are questions that require digging into the literature, using simple math modeling, simulations and thinking about how the dynamic system will respond in different parameter regimes.”

Venkadesan worked on the change in plans with his graduate student teaching fellows Khoi Nguyen, Neelima Sharma, and Ali Yawar, and undergraduate lab assistant (ULA) Sinem Sinmaz ‘20.

Preparation included looking at existing ventilator designs and identifying areas for improvement.

“Some of the dangers that we've come across in basic systems include pumping in too much volume and expanding the lungs beyond normal capacity, which can cause tissue damage,” Khoi Nguyen said. “There are lots of complications in basic systems that aren't well-controlled.”

The goal isn’t for the students to produce a ventilator by the end of the semester, although that would be the moonshot, but to contribute the pool of ideas on this problem that’s being generated by the larger Yale community. With all of his students thinking about the same problem, Venkadesan said, much progress can be made. After all, he noted, one really good idea can make a big difference.

“The people who are teaching this class could think about this on our own, but four brains pale in comparison to what 31 other brains could do,” he said.

Undergraduate Lab Assistant Sinem Sinmaz took the course last year, and while she enjoyed building the robot at the time, she thinks that students now would feel distant to that project in the current circumstances. Work on ventilator design adds a whole new dimension to the course, she said.

“I think it has a really good pedagogical value and goes a little deeper in the theoretical side of what mechatronics is with something a little more current to their lives,” she said. “It definitely moves them forward with an understanding of what mechatronics is and how it affects our lives.”