Remotely, Ventilator Device and Other Projects Continue On

The course Computer-Aided Design (MENG 400), taught by Ronald Adrezin, involves a fair amount of hands-on work. Although the class operated remotely the second half of the semester when the campus shut down to prevent the spread of COVID-19, students, faculty and staff pulled together to get the work done.

One example is the project of Paul Stankey ’21, in which he built a device that modifies a conventional ventilator to treat up to three patients at a time. Before leaving for spring break, a ventilator project wasn’t part of his plans - and then everything changed.

“Prof. Adrezin recommended that I do something relevant, and with my biomedical background, this seemed like a good fit,” he said.

So they sat down and worked through some possible designs for it and ran a couple computer simulations.

So they sat down and worked through some possible designs for it and ran a couple computer simulations.

“We had some conversations regarding the pandemic response, and Paul was the one who came back about the ventilator,” Adrezin said. “When he said something about splitting it two ways, I said ‘We know that that’s being done - why don’t you try splitting it three or four ways?’”

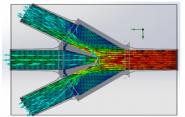

The final design featured one inlet that would attach to a tube from the ventilator and then three outlet tubes that go to patients. “And there’s a type of gate system where you can open or shut the gate, depending on how much air you want to let through to the center one and then split it off to the sides,” Stankey said.

The design takes more work than simply splitting airflow multiple ways.

“We had been reading a lot of articles about this and that is one of the main challenges because you would need to volume-match the patient's lungs - that’s a major concern with it,” he said. “A 6-foot, 200-pound male would have a different lung capacity than, say, a five-foot-one patient. They might need 600 milliliters of oxygen per breath while the 5-1 patient might need something less.”

Despite the new circumstances, the multi-patient ventilator and other projects in the class - these include vending machines, coffee grinders, race cars, stents, HVAC systems, aircraft, and an automatic system to brew tea - continued on, with the students learning everything from finite element analysis to fluid dynamics.

“This has been a new experience,” Adrezin said. He noted that the support from the SEAS staff, from obtaining the necessary equipment to answering technical questions, was crucial in making the shift to a remote classroom. Having the help of Glenn Weston-Murphy, engineering design advisor, he said, was particularly critical, especially when it came to questions about animations and SolidWorks.

For his part, Weston-Murphy said the basic principles of engineering remained the same in the new situation. This includes, for example, conveying to the students the need to assess the available tools and how to best use them, how to optimize their design, and designing for the functionality of the work.