Maintaining Lab Continuity in the Time of COVID-19

When Yale took the necessary step of moving classes online to mitigate the spread of Covid-19, it presented a particular challenge for courses that focus on building complex devices and other hands-on projects. At the School of Engineering & Applied Science, which has no shortage of such courses, staff and faculty mobilized quickly to ensure that students will be able to continue working on their projects and lab courses, even miles from campus while working from their homes.

It’s a process full of trial and error, requiring them to adapt quickly to a situation that changes daily and sometimes hourly. The situation is unprecedented, and that means creating new solutions in real time.

It’s a process full of trial and error, requiring them to adapt quickly to a situation that changes daily and sometimes hourly. The situation is unprecedented, and that means creating new solutions in real time.

“We’re prioritizing and focusing to quickly establish continuity,” SEAS Deputy Dean Vincent Wilczynski said. “From remote locations and in social isolation, we’re marshaling on to get this accomplished.”

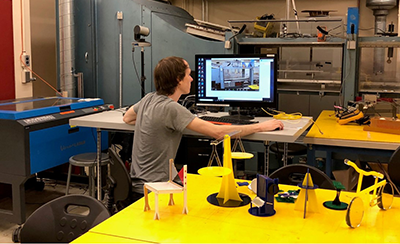

Medical Device Design & Innovation (MENG/BENG 404) breaks students up into teams to develop innovations for healthcare professionals - past projects have included organ transportation equipment and a device for concussion treatment - a process that typically requires the space and resources of the Center of Engineering Innovation & Design (CEID). Daniel Wiznia and Steven Tommasini, co-teachers of the course, teamed up with the staff of the CEID to come up with a plan.

“We had such an incredible first half of the semester with the students,” said Wiznia, assistant professor of orthopedics and rehabilitation. “The students learned so much and Steve and I were just very impressed and so happy to see the dedication the students had. So, then I was thinking, ‘I hope we don’t cancel the second half of the semester.’”

CEID Design Fellows Antonio Medina and Ashlyn Oakes have been working with Wiznia and Tomassini on a plan to 3D print components for the student teams’ projects. Wilczynski, director of the CEID, is giving access to a milling machine from his home. Joe Zinter, assistant director at the CEID, and design mentor Lawrence Wilen have also been working to coordinate efforts with the Medical Device Design course as well as with Profs. Julie Zimmerman and Paul Anastas, who are teaching Green Engineering at the CEID.

Between those efforts as well as virtual rooms held through Zoom and other adjustments, Wiznia is hopeful that the course will be just as rewarding as planned.

“For the second half, we’re going to be able to give them a very good experience, even though it’s going to be remote,” he said.

At the Greenberg Engineering Teaching Concourse (GETC), the staff acted quickly to get what they needed to keep courses going online.

“The special equipment we ordered was a remote-controlled webcam and some extra mics and we had that set up on a cart so we could roll it into the lab you're working in,” said Katherine Schilling, associate research scientist. “One person, while they’re doing the experiment, could actually move the camera around and record themselves talking in front of the equipment.”

The staff quickly made a video demonstrating to faculty how they can use the equipment at the labs to film their lab lessons, including some helpful tips (don’t wear a white lab coat - you’ll blend in with the whiteboard). For Chemical Engineering 412, Schilling and teaching fellows created made videos of lab lessons for the remainder of the semester

The staff quickly made a video demonstrating to faculty how they can use the equipment at the labs to film their lab lessons, including some helpful tips (don’t wear a white lab coat - you’ll blend in with the whiteboard). For Chemical Engineering 412, Schilling and teaching fellows created made videos of lab lessons for the remainder of the semester

“This way, the students can get in lab experience and get their eyes on the equipment,” she said. “Because they’re going to be doing data analysis of either new data or previously existing data from other student groups from earlier in the term.”

To get everyone on board, the staff is holding a trial session to make sure that everyone can get online and make sure it all works out.

“Via Zoom, we’re doing live pre-lab lectures and we’re going to have office hours where students can log-in and ask questions,” Schilling said. “I think it’s going to work - we have a really good team!”

Glenn Weston-Murphy, engineering design advisor, noted that keeping a project-based class going in these circumstances is challenging, but they’ve made a lot of progress in a short time.

“We have data sets from previous years or earlier this year, so for those students who haven’t seen or touched the apparatus, we’re giving them video demonstrations of those experiments,” he said.

For some of the courses, they’re working with the faculty to give the students the resources needed to detail the plans of their projects, even if they’re not able to physically build those projects.

“We want them to detail those things to the level where someone skilled in the art of the documentation could replicate what it is they’re talking about - software code, hardware drawings, computer-assisted design models, and wiring diagrams,” Weston-Murphy said. “We’re trying to give them a visceral experience, virtually. We’re trying to fill the gaps wherever we can to make the experience for everybody successful and in the end as educational as possible.”

Kevin Ryan, research support specialist, spent a few days in his home studio assembling kits for Electrical Engineering labs. Those kits will be sent out to each of the students to work on at home. At the Machine Shop in Becton, research support specialist Nicholas Bernardo has been assisting graduate students and faculty in their use of the equipment there on various projects.

The CEID has long served not only as a makerspace for the Yale community, but also as a social hub. Zinter wants that to continue even as it moves operations online.

“Instead of putting our hands in the air, we're putting our foot on the gas and transitioning a lot of our programs to online formats,” he said. “We’ll be delivering workshops and training sessions and we’re going to continue to move the programming online.”

The CEID staff will continue to hold training sessions on how to use CEID equipment, including the MakerBot and sewing machine. The popular Wednesday night workshops as well as their Friday Make or Break study breaks will move to an online format.

“The current situation presents a tremendous opportunity to engage its members in new ways and demonstrate the strength and resiliency,” Zinter said.