ENAS 118: Artful innovations that carry weight (and make surgery go easier)

From the gym to the museum to the hospital, the students in Engineering Innovation & Design (ENAS 118) applied their problem-solving skills throughout the campus. Taught by SEAS senior research scientist Larry Wilen and SEAS Deputy Dean Vince Wilczynski, the course tapped the expertise of faculty and staff from numerous disciplines throughout Yale.

For each of these projects, the student teams worked with their clients - people who encounter these issues regularly and simply want a better way to tackle them. Most of the work took place in the John Klingenstein '50 Design Lab at the Center for Engineering Innovation & Design (CEID), but the students also made field trips to the operating room at Yale-New Haven Hospital, the Payne Whitney Gymnasium, the Yale University Art Gallery (YUAG) and Institute for the Preservation of Cultural Heritage (IPCH) at Yale's West Campus.

The Science of Color

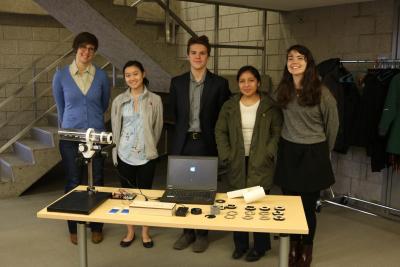

Temperature, humidity and ultraviolet light can cause paint colors to fade over time. It’s such a slow process, though, that it’s hard to tell when it’s happening until the damage is pretty far along. Working with Kate Schilling, associate research scientist at IPCH and Cynthia Schwarz, a paintings conservator for the YUAG, the team of Matt Albritton ’22, Mary Callanan ’22 Veronica Chen ’21, and Sandra Amezcua Rocha ’22 set out to find a way to detect and track any fading that’s taking place.

Temperature, humidity and ultraviolet light can cause paint colors to fade over time. It’s such a slow process, though, that it’s hard to tell when it’s happening until the damage is pretty far along. Working with Kate Schilling, associate research scientist at IPCH and Cynthia Schwarz, a paintings conservator for the YUAG, the team of Matt Albritton ’22, Mary Callanan ’22 Veronica Chen ’21, and Sandra Amezcua Rocha ’22 set out to find a way to detect and track any fading that’s taking place.

They designed and built a device in which a camera takes daily pictures of the artwork, transmits it to a computer, where algorithms analyze the red-blue-green (RBG) values of each pixel. At the same time, a light sensor - also connected to a computer - picks up information about the amount and type of light that the art is being exposed to.

Measuring the Surface of Art

Also working with Schilling and Schwarz, the team of Onora Best ’22, Tanushree Burman ’22, Ihea Inyama ’22, and Evan Lipton, ’22 developed a new way to measure the surface conductivity and Ph levels of acrylic paintings.

Also working with Schilling and Schwarz, the team of Onora Best ’22, Tanushree Burman ’22, Ihea Inyama ’22, and Evan Lipton, ’22 developed a new way to measure the surface conductivity and Ph levels of acrylic paintings.

These measurements, which are necessary for matching the right cleaning solutions for the specific artwork, are commonly performed using either one of two methods - both of which have their drawbacks. In one, a drop of water is placed directly on the canvas and then tested. It’s accurate, but potentially damaging to the artwork. The other involves placing agar gel drops on the painting. It’s less damaging, but also less precise and more time-consuming.

Setting out to improve the gel method, the team developed a syringe that allowed conservators to standardize the size and thickness of the gel drop - variations can skew the results - and handle it more easily. In the team’s device, the gel never leaves the syringe, so there’s no need to use potentially damaging tweezers to remove it.

Making New Ancient Jewelry

For a third art-related project, this time with Carol Snow, deputy chief conservator and Alan J. Dworsky, senior conservator of objects, students designed a way for visitors to take a more active role in a new exhibit at the Yale University Art Gallery.

For a third art-related project, this time with Carol Snow, deputy chief conservator and Alan J. Dworsky, senior conservator of objects, students designed a way for visitors to take a more active role in a new exhibit at the Yale University Art Gallery.

For an exhibit that incorporates ancient jewelry, Snow was looking for something that allowed visitors to do more than just look at the jewelry. The team of Phyllis Mugadza ’21, Nathan Stern ’22, Josh Vogel ’22, and Alexandria Wynn ’22 came up with system in which visitors could actually replicate the jewelry and even take a piece of it home with them. They focused on a method known as repoussé and chasing, one of the oldest known jewelry-making techniques. It involves taking a piece of heated metal and raising it from the back (that’s the repoussé part), which etching a design from the front (chasing). The students fashioned an etching tool out of a hollowed out blowtorch - nonfunctioning, for safety reasons - which featured an LED light inside to replicate the flame.

A High-Tech Update to Weightlifting

For many athletes, squats are an essential part of weight training. The problem is that they’re tough to do correctly, and there’s not always someone around to coach. Working with Thomas Newman, director of sports performance and innovation, the team of Holly Basile ’22, Lillie Ketterson ’21, Gustavo Parajon ’22, and Katie Skoff ’22 designed and built a device that beeps (a sound taken from Super Mario Brothers) when the athlete has crouched down far enough to qualify as a proper squat. Things get knocked around a lot in a gym, so the device was also designed for durability. A key component is the time-of-flight sensor, which measures the distance between the athlete’s body and the floor.

For many athletes, squats are an essential part of weight training. The problem is that they’re tough to do correctly, and there’s not always someone around to coach. Working with Thomas Newman, director of sports performance and innovation, the team of Holly Basile ’22, Lillie Ketterson ’21, Gustavo Parajon ’22, and Katie Skoff ’22 designed and built a device that beeps (a sound taken from Super Mario Brothers) when the athlete has crouched down far enough to qualify as a proper squat. Things get knocked around a lot in a gym, so the device was also designed for durability. A key component is the time-of-flight sensor, which measures the distance between the athlete’s body and the floor.

The device also has a mode that coaches athletes when they have to hold the squat - a high tone indicates they’re haven’t crouched low enough, and a low tone tells them that they’ve gone down too far.

At the Gym: Taming the Electronic Chaos

With more than 30 varsity teams, and hundreds of athletes, the Payne Whitney Gym can be a busy place. Also busy is the charging station for all the athletes’ electronic devices. In the wild thicket of cords from the many devices, things go awry: cords slip out of their sockets, some go missing, devices go uncharged. In an era of high-tech training where data collection is a key component to working out, this is no trivial matter.

With more than 30 varsity teams, and hundreds of athletes, the Payne Whitney Gym can be a busy place. Also busy is the charging station for all the athletes’ electronic devices. In the wild thicket of cords from the many devices, things go awry: cords slip out of their sockets, some go missing, devices go uncharged. In an era of high-tech training where data collection is a key component to working out, this is no trivial matter.

The student team of Pranav Avasarala ’22, Alara Degirmenci ’22, Fernando Hernandez ’22 and Emma Pindur ’22 was charged with making sure they actually get charged and somehow tame the mass of cords. With some 24 devices and 183 wires to work with, this is no small feat. They found an elegant solution by developing a user-friendly system that lets uses know - via a blinking green LED light - that all is OK with their electronic device.

Taking the Mess Out of Surgery

Blood, fat and anything else that gets in the way can make things tricky for surgeons. To clear the way, a vacuum tube is used to suck away the debris. However, it often gets clogged - sometimes several times during the same procedure, and de-clogging can take up to 15 minutes each time. Working with Daniel Wiznia, assistant professor of orthopedic surgery, the team of Charlie Markert ’21, Enrique Martinez Padres ’22, Thuy Pham ’22, and Gavrielle Welbel ’22 developed a new suction tube designed to make things easier.

Blood, fat and anything else that gets in the way can make things tricky for surgeons. To clear the way, a vacuum tube is used to suck away the debris. However, it often gets clogged - sometimes several times during the same procedure, and de-clogging can take up to 15 minutes each time. Working with Daniel Wiznia, assistant professor of orthopedic surgery, the team of Charlie Markert ’21, Enrique Martinez Padres ’22, Thuy Pham ’22, and Gavrielle Welbel ’22 developed a new suction tube designed to make things easier.

To make it easy to use, the students focused on making a system with few moving parts. They developed a device with a wider tip than the tubes that are in wide use. Testing it on a concoction of flour, water, corn syrup solution, and 3D printed bones, they found that it works faster than conventional devices, with 95% less clogging.