A Better Way To Make New Metallic Glasses

With the pliability of plastic and a steel-like strength, metallic glasses are already being used in a variety of applications, from golf clubs to phone casings. Limiting their potential, though, are the painstaking and time-consuming methods of developing new glasses.

“Essentially, the physics behind glasses is painfully difficult, and the tools we have developed rely on the crystallized structure,” says Jan Schroers, professor of mechanical engineering & materials science. Schroers is part of a team of researchers from Yale, Duke University and Harvard University who have developed a way to better predict what alloy combinations will result in metallic glasses. Their results are published Aug. 2 in Nature Communications.

Metallic glasses form when molten metal is cooled too fast for its atoms to arrange in the typical structured and crystalline order. The amorphous structure that forms can result in a material with some very useful properties – very high strength and elasticity, and high corrosion resistance, for example. All the existing known metallic glasses, however, have their pros and cons. Zirconium-beryllium based metallic glasses pose health risks, for instance. Platinum-based glass exhibit exciting properties, but they’re also extremely expensive, which rules them out as a material for wide spread applications.

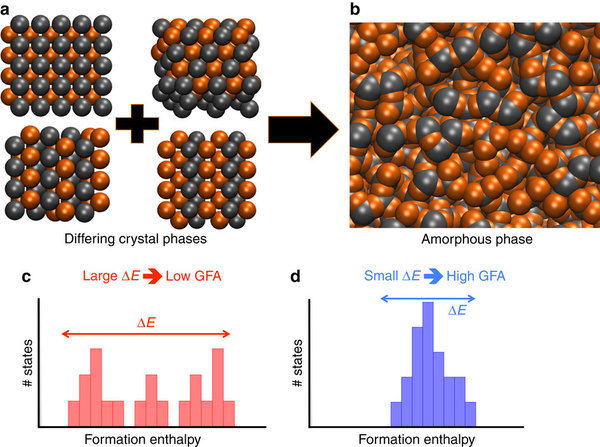

The researchers describe in the paper their method of finding new combinations of elements to form metallic glasses, which involves computing and comparing the many phases of different structures and energies that could be found within alloy systems.

The researchers discovered that when many phases with similar energies exist, a “confusion” occurs as the material tries to crystallize. That is, the material can’t “decide” which crystalline structure it wants to converge to. That leads to a randomized structure, and the combination of elements readily forms a metallic glass.

“If you can learn anything about the glass by looking at the crystal, that would be very powerful - and that’s essentially what we have done,” Schroers said. “From a purely technological point of view, we’ve make it much more efficient to discover new metallic glasses. “

To measure the “confusion,” the study’s senior author, Stefano Curtarolo, professor of mechanical engineering and materials science at Duke, uses combinatorial simulations to rapidly analyze the crystalline structures for thousands of potential alloys.

Schroers and Vlassak take the data, choose the most promising ones, and make alloys in their lab. The researchers were able to correctly identify 73 percent of the combinations that led to metallic glasses — a number they expect to increase as they add to the structural information and simulations stored in their database. Based on their initial work, they believe that a vast number of metallic glasses are out there to be discovered.