Student Summer Project Highlight: New Tests for Face Shields

Neither summer nor social distancing slowed down the innovations for this year’s cohort of the Yale Center for Engineering Innovation and Design’s Summer Fellowship. Today we feature one team’s work on testing proposals for face shield designs.

J.R. Stauff '23 and David Ewing ‘23 spent their eight weeks in the program helping the nation of Colombia develop guidelines for the use of face shields.

It started with a national contest in Columbia for face shield designs, organized by the United Nations Development Program (UNDP), as a way to prevent the spread of COVID-19. After receiving more than 300 submissions, a panel of experts chose three finalists. Looking to get data specific to these three designs, UNDP member Alejandro Pacheco - a 2014 Maurice R. Greenberg Fellow at Yale - contacted his former advisor, a connection that led him to the Summer Fellows.

It started with a national contest in Columbia for face shield designs, organized by the United Nations Development Program (UNDP), as a way to prevent the spread of COVID-19. After receiving more than 300 submissions, a panel of experts chose three finalists. Looking to get data specific to these three designs, UNDP member Alejandro Pacheco - a 2014 Maurice R. Greenberg Fellow at Yale - contacted his former advisor, a connection that led him to the Summer Fellows.

“I said having someone independent, especially from Yale, would be extremely useful,” he said.

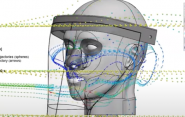

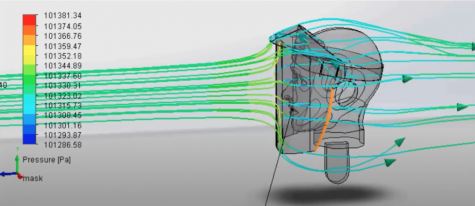

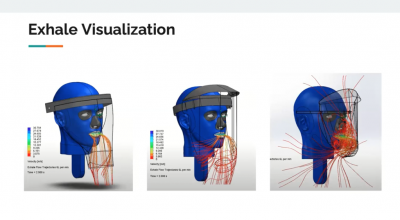

Stauff and Ewing were tasked with developing computer simulations to assess which of the three models is most effective at safely redirecting airflow to prevent coronavirus for both wearers and those around them. The methods they used to do this would have to be reproducible and apply to many different designs.

To build the simulations, the two students took the three physical face shields and designed 3D models for each. They combined those models with a mannequin head and built a test chamber in accordance with international test standards.

The three qualities that they focused on were facial coverage, effective curvature and air redirection, and ventilation and internal air flow. While each of the models had their strong points, Stauff and Ewing deemed the model called “re.co” as the best overall, adding that “sometimes, the simplest design is the most effective. They noted that it displayed excellent protection from airstreams from above and in front of the mask. For the benefit of future designs, they also listed the best qualities of each mask.

Juan David Martin Jimenez, one of the UNDP partners working on the project with Pacheco, noted that they’ve been meeting with representatives from the World Health Organization about the face shield designs. He said the feedback from the Yale students was very helpful, and confirmed many of their hypotheses. The nature of the situation, Pacheco added, required that their work gets done at a much faster rate than normal, and the Summer Fellows’ contributions were a big part of that.

“This is a very good example of acceleration,” he said. “It’s something that would normally take one year or more, and was done in one month.”

Stauff and Ewing have analyzed two more shields in addition to the three models that the UNDP sent and created a second method of testing, in which they measure the pressure on the faces of the mannequin to get a quantitative comparison between the shields.