Start-up ARIX Promises Better Pipe Maintenance Through Robotics

Why manually inspect miles of pipes for corrosion (a process that often involves hanging from other pipes) when you can get robots to do that for you?

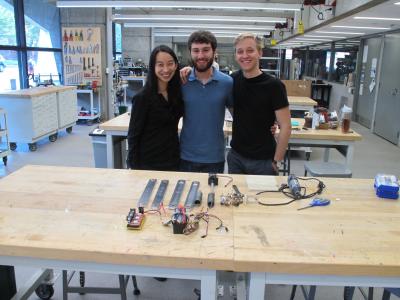

It’s an idea that spawned ARIX, a company that combines the talents of School of Management student Dianna Liu ’18 and two recent SEAS grads Petter Wehlin ’17 and Bryan Duerfeldt ’17. The start-up has enjoyed an auspicious first year. In April, the company won the $25,000 Miller Prize from the Tsai Center for Innovative Thinking at Yale and has attracted the interest of potential investors.

It’s an idea that spawned ARIX, a company that combines the talents of School of Management student Dianna Liu ’18 and two recent SEAS grads Petter Wehlin ’17 and Bryan Duerfeldt ’17. The start-up has enjoyed an auspicious first year. In April, the company won the $25,000 Miller Prize from the Tsai Center for Innovative Thinking at Yale and has attracted the interest of potential investors.

The idea for the company began when Liu was working at one of ExxonMobil’s refineries in Louisiana and saw the slow, labor-intensive process the industry has for tracking and preventing pipe corrosion. Finding that there was no optimal alternative, she came up with a plan for one and came to the Yale School of Management specifically to get it off the ground.

“One of the reasons I went to Yale is because the School of Management is so integrated with the rest of the school,” said Liu, the company’s CEO. “I thought it would be a lot easier to find interested engineers here than if I went to some of the other business schools.”

In the first month, she met with Wehlin and Duerfeldt, both mechanical engineering students. They initially worked part-time on the prototype and then joined ARIX full-time after graduation.

The company combines robotics and predictive data analytics. They’re focusing on the oil industry for now, although they may expand to other industries at a later time. The current process for inspecting pipes at refineries is slow, expensive, and very dangerous.

“They often must build scaffolding or employ rope crews where people hang down from higher pipes. The inspection devices are then used on specific points along the pipe to measure the effects of corrosion,” Wehlin said. “We want to bring in a new paradigm of pipe inspection.”

The system they’re developing would deploy robots that travel on the outside of pipes, able to navigate around obstacles while it conducts an inspection of the pipe. It would then transmit that data to a software program. The program would then provide user-friendly visualization and analytics while integrating with other refinery to provide a holistic view of all a refinery’s assets.

According to a recent government study, corrosion costs the petroleum refining industry $3.7 billion in the U.S alone. Maintenance expenses comprise $1.8 billion out of that amount. Liu says the ARIX system has the potential for not only immediate cost savings in corrosion prevention and maintenance, but even more credits in the long run, thanks to the system’s data analytics.

To get to that point, though, they’re working at the Center for Engineering Innovation and Design (CEID) to refine the prototype. If all goes well, they hope to have a prototype they can field test in about a year. From there, said Duerfeldt, they’ll work on the design to make it suitable for manufacturing.