Developing Scalable Methods for Aligned Membrane Fabrication for Water Purification

Working with colleagues from academia and industry, two Yale engineers are expanding carbon nanotube-based technologies.

Chinedum Osuji, Associate Professor of Chemical & Environmental Engineering, and Menachem Elimelech, the Roberto C. Goizueta Professor of Chemical & Environmental Engineering, are working to develop scalable methods to fabricate vertically aligned carbon nanotube and nanoporous membranes.

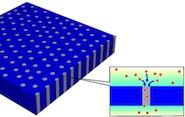

The researchers currently make nanoporous thin films in two different ways. In one approach, they embed vertically aligned carbon nanotubes in polymer films; the pores of the nanotubes themselves can then act as a filtration device. Anything larger than the width of the tubes won’t fit through the film, and can be filtered out.

In the second approach, the researchers use block copolymers that self-assemble; these form structures that are naturally composed of channels, and by removing the material that forms the channels, the researchers produce films that function as size and chemically-selective filters as well.

The researchers’ current efforts directly address two long-standing problems in using carbon nanotubes to create nanoporous membranes: the dual challenges imposed by the need to align the nanotubes vertically in thin films and the requirement that fabrication methods be scalable to large areas.

“A big problem in directing self assembly is that you cannot easily align structures vertically in thin films,” says Osuji. “If you have an anisotopic object, something like a rod or tube or wire, it’s very difficult to make it stand vertically in a thin film.

“Imagine a sheet of paper was a membrane,” he continues, “And you wanted to have tiny nano-scale holes 50,000 times smaller than the width of a human hair [crossing] the paper from the top to the bottom to make a very fancy filtration device. It’s very difficult to do that over large areas of material that could be useful, practically speaking. This is what our research is addressing.”

The attractive feature of carbon nanotubes here is that they have very small pores, making them suitable for the filtration of extremely small objects, even down to the level of a single molecule. If the researchers are successful in developing their scalable nanomanufacturing approach, several exciting applications for such nanoporous membranes would be possible, ranging from water desalination – using the membrane’s filtration properties to remove the salt – to virus filtration and analytical chemistry.

“The compelling feature here is that we have very tight control over the diameter of the pores and their alignment,” says Osuji. “That gives you the best transport capabilities in membrane applications.”

The research is supported by a new $1.2M grant from the National Science Foundation, performed in conjunction with Co-Principal Investigators Rajeswari Kasi of the University of Connecticut and Olgica Bakajin of industry partner Porifera Nano.