Construction of Fuel Cell Catalyst Layers with Nanometer Precision

In the December 19, 2008, School of Engineering & Applied Science website news release, Another Step Forward for Fuel Cell Technology, we covered Professor André Taylor's breakthrough research on a novel technique using supercritical fluids for controllably loading metal particles onto the surface of 1-D carbon supports. Simply, this research promises to reduce the high costs associated with the expensive catalyst, platinum (Pt), used in fuel cell technology by improving its distribution and utilization. In this next phase of research, published in the September 2008, issue of Advanced Functional Materials, Taylor, et al., take another step forward by successfully demonstrating layer-by-layer assembly techniques to construct thin-film fuel cell catalyst layers with nanometer precision. To date, their technique has produced the highest performance for films of this type, with a peak power density of 387 mWcm-2 and a Pt utilization of 3198 mWmgPt-1.

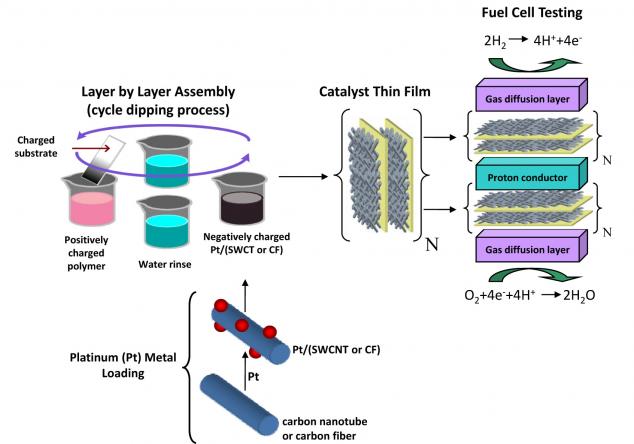

Layer-by-layer (LBL) assembly is a relatively new technique used for the construction of thin-film nanocomposites, which have broad-scale applications, ranging from drug delivery to solid battery electrolytes. Since its publication in Science in 1997, Gero Decher's groundbreaking research on LBL assembly, has become one of the most highly cited publications in the journal and has seen a growing number of citations each year as its relevance becomes widely recognized. In LBL assembly, a substrate is alternatively dipped into positively and negatively charged solutions, which are sequentially deposited as very thin (nanoscale) layers, until the desired number of bilayers is reached. This technique offers a highly simplistic way to create novel multilayer materials that display flexible functionality including semiconducting, metallic, or magnetic properties.

Layer-by-layer (LBL) assembly is a relatively new technique used for the construction of thin-film nanocomposites, which have broad-scale applications, ranging from drug delivery to solid battery electrolytes. Since its publication in Science in 1997, Gero Decher's groundbreaking research on LBL assembly, has become one of the most highly cited publications in the journal and has seen a growing number of citations each year as its relevance becomes widely recognized. In LBL assembly, a substrate is alternatively dipped into positively and negatively charged solutions, which are sequentially deposited as very thin (nanoscale) layers, until the desired number of bilayers is reached. This technique offers a highly simplistic way to create novel multilayer materials that display flexible functionality including semiconducting, metallic, or magnetic properties.

Despite the competitive performance Taylor has demonstrated, he states that the practicality of this research is currently limited to that of a research tool. The LBL assembly method Taylor presents will help to identify the best configuration and morphology as it offers a higher degree of control over the film structure than other methods. The trade-off for such control is often seen in the increased time required for manufacturing. Recent advances in LBL assembly, however, could drastically reduce this assembly time.

As Professor Taylor recognizes, these are exciting times for the development of high performance nanomaterials and devices. While the applications for LBL assembly are wide-spread, Taylor will continue to focus research on improving fuel cell technology, a critical need as we face the looming threat of global climate change and the challenge of gaining energy independence.