Carbon Electronics Get Boost With Novel Oxygen Removal Method

Scientists at Yale University have developed a novel method for dramatically improving the efficiency of electronics made from single-walled carbon nanotubes (SWNTs) that have been “doped,” a chemical process that optimizes their properties. The method, published recently in Nano Letters, exposes the SWNTs to hydrogen fluoride vapor followed by an electrical current to eliminate the oxygen that hinders doping.

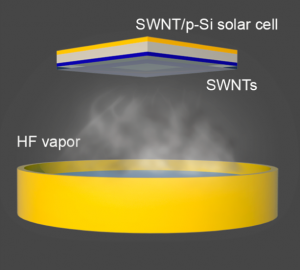

Led by associate professor of chemical & environmental engineering and co-principal investigator André Taylor, the Yale team used their method to produce a SWNT-based solar cell that converts light energy into electrical energy at an unprecedented efficiency. “Our method uses standard clean room processing chemicals and capabilities to create extremely efficient n-type doped CNTs,” said Taylor. “It also provides a stepping stone for the creation of carbon electronics, which could be the next-generation material for computer devices.”

The new method addresses the presence of adsorbed oxygen on the surface of SWNTs, an impurity that can significantly affect conductivity as well as other properties. “But the presence of oxygen is nearly unavoidable because at some point the materials are likely to be in contact with air,” said doctoral candidate and lead author Xiaokai Li, “meaning that all carbon electronics are susceptible to diminished performance unless the oxygen can be removed.”

Most commonly, oxygen removal would be done with the slow and difficult process of high temperature annealing of SWNTs under ultrahigh vacuum or inert gas. The method developed by the Yale team—which also included assistant professor of chemistry and co-principal investigator Nilay Hazari—has two features. The oxygen molecules were first removed from the SWNT surface using a hydrogen fluoride vapor—a process widely used by the semiconductor industry to remove silicon oxide from the silicon surface. Then a constant electric current was applied to the SWNTs, which further removed other potential gases from the surface. The team reports that the combined treatment led to better performance than either treatment step alone or the standard vacuum heating method.

“This novel method builds on our work on carbon nanotube-silicon hybrid solar structures,” said Taylor. “Already we used the method to build a dramatically improved solar cell, but we’re even more excited for where this research will take us next.”